X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

The stage hand - chain hoist can be regarded as a capable little assistant on the stage. It has an exquisite structure, is effortless to install, occupies minimal space, and can fit perfectly into var

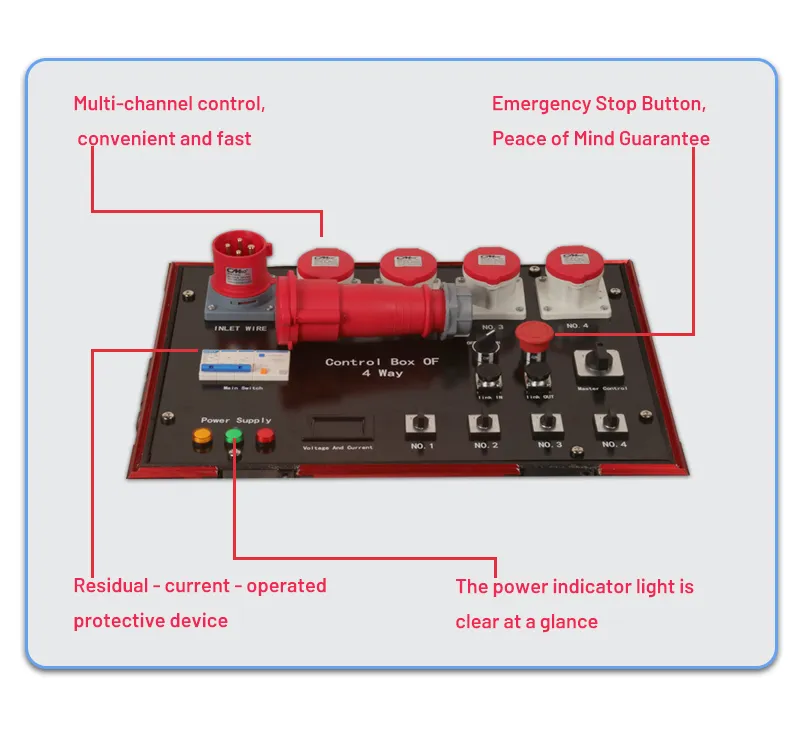

Category : Controller

Get a Quote

Product Details

The inspection of key parts of the stage electric hoist controller involves multiple aspects. The following are the specific inspection contents and methods: Operation Buttons- **Appearance Inspection**: Check whether the surface of the button has damage, cracks, deformation, fading, etc., and ensure that the button's markings are clear and distinguishable, so that operators can accurately operate. - **Touch - feeling Inspection**: Press and release the button to feel whether the operating force is appropriate, and check for any jamming, looseness, or insensitivity. When each button is pressed, the closing of the contact should be clearly felt, and it should quickly reset after release. - **Function Test**: With the electric hoist in a safe state, press the up, down, stop and other buttons respectively, and observe whether the electric hoist can accurately act according to the instructions. At the same time, check whether the emergency stop button can immediately cut off the power supply in an emergency and stop the operation of the electric hoist. Display Screen- **Display Clarity Inspection**: Observe whether the display content on the display screen is clear and complete, and check for problems such as missing strokes, blurring, flickering, or incomplete display. If the display screen malfunctions, it may affect the operator's judgment of the operating status of the electric hoist. - **Data Accuracy Inspection**: Check whether the parameters displayed on the display screen, such as lifting capacity, running speed, height, etc., are accurate. The accuracy of the data on the display screen can be verified by comparing it with actual measurement values or known standard values. - **Brightness Adjustment Function Inspection**: Check whether the brightness adjustment function of the display screen is normal, and whether it can be adjusted to an appropriate brightness according to different ambient light conditions, so that the operator can clearly view the display content in various environments. Control Circuit- **Circuit Connection Inspection**: Open the controller housing and check whether the internal circuit connections are firm, and look for signs of looseness, detachment, oxidation, or corrosion. Focus on checking parts such as terminal blocks, plugs, and sockets to ensure reliable circuit connections and avoid controller failures caused by poor contact. - **Circuit Board Inspection**: Observe whether there are phenomena such as charring, discoloration, bubbling, or component damage on the surface of the circuit board. Check whether there are obvious signs of damage to the electronic components on the circuit board, such as broken leads and cracked casings, for components like capacitors, resistors, and diodes. - **Insulation Performance Inspection**: Use an insulation resistance meter to measure the insulation resistance of the control circuit to ensure good insulation performance. Generally, the insulation resistance of the control circuit is required to be not less than 1MΩ to prevent electric leakage accidents and ensure the safety of operators and equipment.

Relays and Contactors

- **Appearance Inspection**: Check whether the casings of the relays and contactors have damage, deformation, or charring marks, and examine whether their contacts have ablation, wear, or adhesion. If the contacts are severely ablated, it will increase the contact resistance and affect the normal on - off of the circuit. - **Action Flexibility Inspection**: Manually operate the relays and contactors to check whether the armatures are flexible in attracting and releasing, and check for any jamming or abnormal noises. Under the energized state, observe whether the actions of the relays and contactors are accurate and reliable, and whether the attracting and releasing times meet the specified requirements. - **Coil Resistance Measurement**: Use a multimeter to measure the coil resistance of the relays and contactors, and compare the measured value with the rated value to judge whether the coil is normal. If the coil resistance value differs significantly from the rated value, there may be faults such as short - circuit, open - circuit, or inter - turn short - circuit in the coil.Signal Transmission Components- **Sensor Inspection**: Check various sensors connected to the controller, such as limit sensors, weight sensors, etc. Check whether their appearance is intact and the installation is firm. Examine whether the signal line connections of the sensors are normal, and look for any damage, breakage, or poor contact. By simulating actual working conditions, check whether the sensors can accurately detect the corresponding signals and transmit them to the controller.

- **Communication Interface Inspection**: If the controller has a communication interface, check whether the interface is clean, free of oxidation, and the connection is firm. Use professional testing tools or software to check whether the communication function of the communication interface is normal, and whether it can accurately and stably transmit data with other devices (such as control consoles, host computers, etc.).

https://studio.youtube.com/video/HrpaZNO0LqQ

If you need further consultation on product details, please contact Google email

Gmail : info@kemeihoist.com

zyj@kemeihoist.com

Website: https://www.kemeihoist.com/

WhatsApp:+86 13920508123

Previous: Stage Electric Hoist Controller

RELATED PRODUCTS .

Customizable Sling Belts With "design-on-demand" at their core, customizable sling belts deeply integrate materials science, mechanical principles, and scenario-specific needs, making them i...

As the "brain" of lifting tools, the performance of truss hoist controllers directly impacts stage effects and operational safety. From manual operation to intelligent linkage, different typ...

The smooth manual chain hoist, with its reliable mechanical structure and operational flexibility, has become an indispensable manual lifting tool in scenarios such as stages, industrial environments,

Efficiently complete rapid setup of booth trusses, high-altitude suspension of product display racks, or multi-angle display of dynamic advertising light boxes. For example, at a technology exhibition

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record