X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

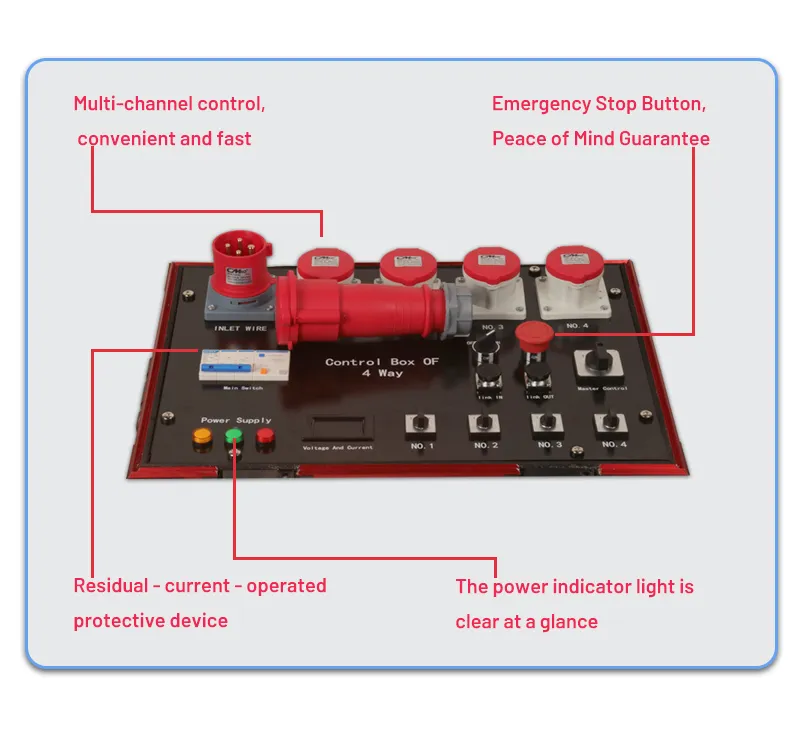

The stage electric hoist controller features convenient operation, flexible linkage, exquisite design, and portability. It precisely controls the operation of the stage electric hoist, enabling the fl

Category : Controller

Get a Quote

Product Details

Product Name: Stage Electric Hoist Controller

Product Type: Controller

Product Description: Tianjin Kemei Machinery Manufacturing Co., Ltd. is a modern manufacturing enterprise integrating independent R & D, manufacturing, and sales. It is located in the beautiful coastal city of Tianjin, enjoying a unique geographical location, convenient transportation, and efficient logistics. The company is committed to the development and production of stage entertainment hoisting products. Its main products include stage - specific chain electric hoists, stage - specific hand chain hoists, black lifting slings, group control boxes, rail grippers, and auxiliary products. These products are widely used in the fields of truss construction for concerts, conference halls, exhibition booth construction, high - end customized weddings, and various celebration performances. Product Specifications: 1. The main components are of imported brands and have passed aging tests, ensuring durable and stable quality. 2. The controller is a heavy - duty knob reversing switch, enabling the linkage of multiple controllers. 3. With an aviation - box - designed shell, it is convenient and quick to carry and transport.

The storage methods of the stage electric hoist controller when not in use are as follows: Cleaning

- Surface Cleaning: Wipe the surface of the controller with a clean and soft damp cloth to remove dust, stains, and debris. For stubborn stains, a small amount of neutral detergent can be dipped for wiping, but be careful to avoid the detergent entering the interior of the controller. - Internal Cleaning: If conditions permit, the controller housing can be opened (to be operated by professionals to prevent damage or electric shock). Use compressed air or a soft brush to clean the internal dust, preventing dust accumulation from affecting the performance of electronic components. Inspection - Electrical Connection Inspection: Check whether the connection parts of the controller's power cord, control line, etc. are loose, damaged, or oxidized. If loose, tighten them in a timely manner. Replace damaged wires and clean oxidized connectors. - Button and Display Screen Inspection: Press each button to check whether it can rebound and respond normally, and whether there is any jamming or poor contact. At the same time, check whether the display screen is displaying normally, and whether there are problems such as missing characters or screen flickering. - Function Test: A simple function test can be carried out before storage. For example, control the electric hoist to perform short - distance lifting operations to ensure that the controller functions properly. If problems are found, repair or replace the controller in a timely manner. Storage Environment - Dry and Well - ventilated: Store the controller in a dry and well - ventilated place to avoid the internal components of the controller getting damp, rusty, short - circuited, or damaged due to a humid environment. The humidity is generally controlled at 40% - 60%. - Appropriate Temperature: The temperature of the storage environment should be maintained between - 10°C and 40°C to prevent high temperatures from accelerating the aging of controller components or low temperatures from causing a decline in battery performance and embrittlement of the shell. - Avoid Magnetic Field Interference: Keep away from strong magnetic field equipment such as large - scale motors and transformers to prevent the magnetic field from interfering with the controller's electronic components and affecting their performance and data storage. - Anti - corrosion and Dust - proof: Do not place the controller in an environment with corrosive gases or liquids to prevent the corrosion of the shell and internal components. At the same time, a dust cover or storage box can be used to cover or store the controller to prevent dust from entering. Other Precautions - Proper Placement: Place the controller in a stable position, avoiding dropping and collision to prevent the shell from cracking or the internal components from being damaged. If possible, place it in a dedicated storage box or on a shelf. - Disconnect the Power Supply: Be sure to disconnect the controller from the power supply to prevent damage to the controller or occurrence of safety accidents caused by accidental power - on. - Record Information: Information such as the last use time and inspection status can be marked on or next to the controller so as to understand its status when using it next time.

- Regular Maintenance: Even if the controller is not in use, it should be inspected and maintained at regular intervals (such as every 3 - 6 months), including cleaning, function testing, etc., to ensure its good performance.

RELATED PRODUCTS .

Customizable Sling Belts With "design-on-demand" at their core, customizable sling belts deeply integrate materials science, mechanical principles, and scenario-specific needs, making them i...

As the "brain" of lifting tools, the performance of truss hoist controllers directly impacts stage effects and operational safety. From manual operation to intelligent linkage, different typ...

The smooth manual chain hoist, with its reliable mechanical structure and operational flexibility, has become an indispensable manual lifting tool in scenarios such as stages, industrial environments,

Efficiently complete rapid setup of booth trusses, high-altitude suspension of product display racks, or multi-angle display of dynamic advertising light boxes. For example, at a technology exhibition

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record