X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

The controller of the stage electric hoist controls the electric hoist through the control circuit. Take the push - button controller as an example. When the up button is pressed, the circuit inside t

Category : Controller

Get a Quote

Product Details

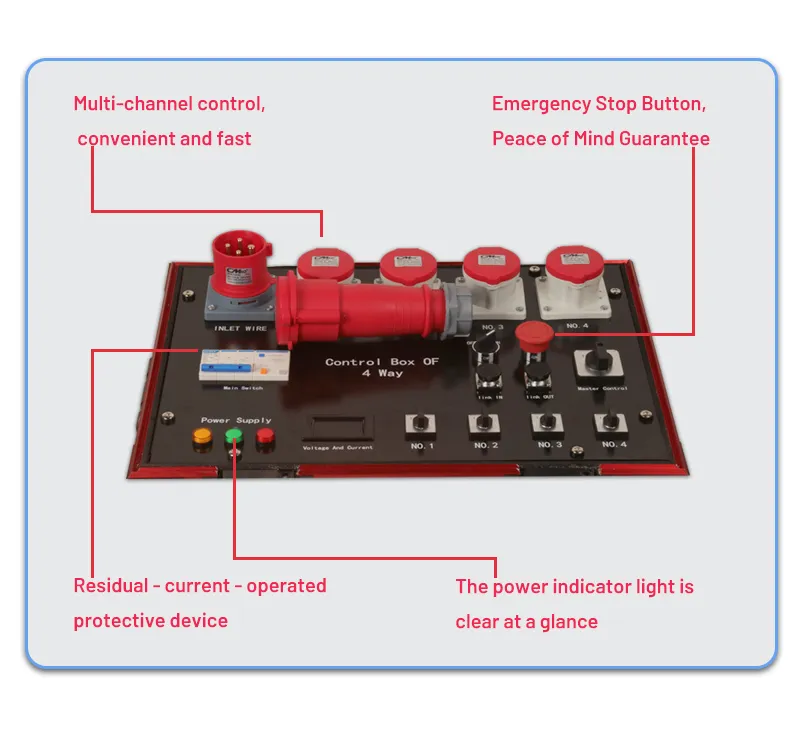

The controller of the stage electric hoist is a core device that ensures the safe, stable, and precise operation of the electric hoist. It mainly consists of the following parts: Operation Input Section - **Button Operation Panel** - This is quite common in traditional stage electric hoist controllers. Generally, it is equipped with basic function buttons such as up, down, and stop. Some may also have speed - adjustment buttons. Operators send commands to the controller by pressing the corresponding buttons to achieve various actions of the electric hoist. These buttons usually have a good tactile feel and durability to meet the needs of frequent operation. - **Remote Control** - It belongs to a wireless operation input device, which facilitates operators to control the electric hoist from a certain distance away. The remote control is also equipped with function buttons similar to those on the button operation panel and may be equipped with a display screen to show information such as the operating status of the electric hoist. Its signal transmission adopts a specific coding method to ensure the accuracy and security of signal transmission and avoid being interfered by the outside. - **Touch Screen** - This is more commonly seen in more advanced controllers. The touch screen can provide an intuitive operation interface. Operators can perform various operations by touching icons, menus, etc. on the screen. It can not only achieve basic lifting and lowering control but also perform functions such as parameter setting and fault diagnosis. The touch screen has good interactivity and can display rich information, such as the current position of the electric hoist, the load weight, the running speed, etc. Control Processing Section - **Main Control Chip** - It is the core brain of the controller, usually using a single - chip microcomputer or a programmable logic controller (PLC). The main control chip receives instructions from the operation input section and analyzes and processes them. According to preset programs and algorithms, it calculates the corresponding control signals to control the operation of the electric hoist motor. The main control chip also has data storage and processing capabilities, which can record the operating parameters and fault information of the electric hoist for subsequent maintenance and management. - **Control Circuit** - It is composed of various electronic components such as relays, contactors, resistors, and capacitors. The control circuit accurately controls the motor of the electric hoist according to the control signals sent by the main control chip. It can achieve functions such as forward and reverse rotation, speed regulation, and braking of the motor. At the same time, the control circuit also has protection functions such as over - current, over - voltage, and under - voltage protection. When an abnormal situation occurs, it can cut off the circuit in a timely manner to protect the motor and other equipment from damage. Feedback Detection Section - **Position Sensor** - It is used to detect the position of the hook or heavy object of the electric hoist. Common position sensors include photoelectric sensors and travel switches. The photoelectric sensor detects the position of an object by emitting and receiving light, which has the advantages of high precision and fast response speed. The travel switch triggers a signal through mechanical contact. When the electric hoist reaches the preset position, the travel switch acts and feeds back a signal to the controller. The controller controls the electric hoist to stop or change the running direction according to this signal. - **Weight Sensor** - It is installed on the hook or other stressed parts of the electric hoist to monitor the weight of the lifted heavy object in real - time. The weight sensor converts the weight signal into an electrical signal and transmits it to the controller. When the weight of the heavy object exceeds the rated load of the electric hoist, the controller will send an alarm signal and take corresponding protective measures, such as stopping the lifting operation to prevent the equipment from being damaged due to overloading. - **Speed Sensor** - It is used to measure the running speed of the electric hoist. Common speed sensors include encoders and Hall sensors. The speed sensor feeds back the speed signal to the controller. The controller adjusts the speed of the motor according to the set speed value to ensure that the electric hoist runs at a stable speed. Power Supply Section - **Power Module** - It provides a stable power supply for various parts of the controller. It converts the input mains power into voltages suitable for the internal circuits of the controller, such as 5V, 12V, 24V, etc. The power module usually has functions such as filtering and voltage regulation to ensure the stability and purity of the output voltage and avoid the impact of power fluctuations on the normal operation of the controller. - **Backup Power Supply**

- To ensure that the electric hoist can stop safely or complete necessary operations in case of sudden power outages, some controllers are also equipped with a backup power supply, such as a battery. The backup power supply automatically switches to supply power when the mains power is interrupted, providing power support for functions such as the emergency braking of the controller and the electric hoist.

https://studio.youtube.com/video/HrpaZNO0LqQ/edit

RELATED PRODUCTS .

Customizable Sling Belts With "design-on-demand" at their core, customizable sling belts deeply integrate materials science, mechanical principles, and scenario-specific needs, making them i...

As the "brain" of lifting tools, the performance of truss hoist controllers directly impacts stage effects and operational safety. From manual operation to intelligent linkage, different typ...

The smooth manual chain hoist, with its reliable mechanical structure and operational flexibility, has become an indispensable manual lifting tool in scenarios such as stages, industrial environments,

Efficiently complete rapid setup of booth trusses, high-altitude suspension of product display racks, or multi-angle display of dynamic advertising light boxes. For example, at a technology exhibition

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record