X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

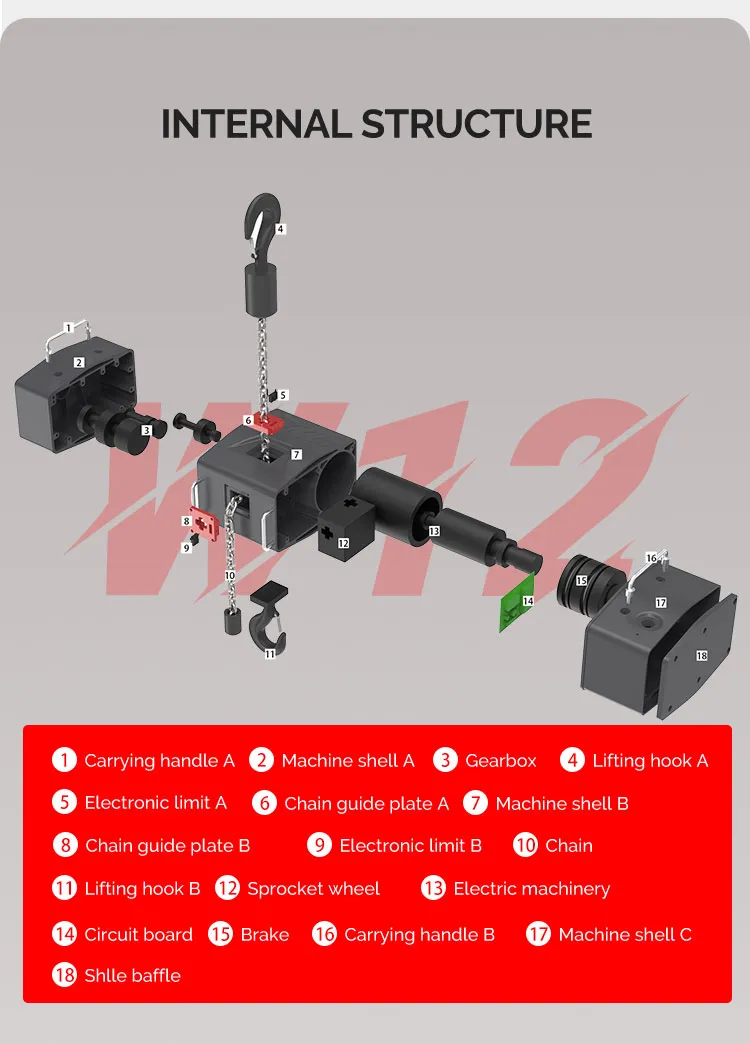

The W12 stage-specific electric hoist, also known as the self- hanging. It is mainly applicable to the construction of commercial stages, stage scenery, audio and lighting arrangements, as well as ban

Category : W12 Stage Electric Hoist

Get a Quote

Product Details

The daily maintenance and repair of stage electric hoists are crucial for ensuring their safe and stable operation. The following are the specific precautions: Precautions for Daily Maintenance 1. **Cleaning** - Regularly clean the dust, oil stains, and debris on the surface of the electric hoist, especially on parts such as the motor, reducer, and chain, to prevent the accumulation of dust and oil from affecting heat dissipation and operating performance. - Wipe the control buttons and display screen with a clean cloth to ensure sensitive operation and clear display. 2. **Lubrication** - Lubricate each lubrication point of the electric hoist regularly according to the requirements of the equipment manual. Generally, the chain needs to be coated with special chain lubricating oil at certain intervals of working hours or operating mileage to reduce the friction between the chain and the sprocket and minimize wear. - Also, regularly add an appropriate amount of grease to the transmission components such as the bearings and gears of the electric hoist to ensure smooth rotation and reduce mechanical losses. 3. **Component Inspection** - Before each daily use or regularly, check whether the hook of the electric hoist has defects such as wear, deformation, and cracks, and whether the opening degree of the hook is within the normal range. If there are any abnormalities, replace or repair it in a timely manner. - Check whether the chain has elongation, deformation, rust, or loose chain pins. If there are any problems, adjust or replace the chain in a timely manner. At the same time, ensure that the chain tension is appropriate, avoiding being too loose or too tight. - Check whether the wire rope of the electric hoist has broken wires, wear, rust, or distortion, and whether the fixed end of the wire rope is secure. If serious damage to the wire rope is found, replace it immediately. - Check whether the braking device of the electric hoist is sensitive and reliable, and whether the braking clearance meets the requirements. The braking performance can be checked through manual operation and no - load and load tests to ensure that it can brake quickly in case of power failure or an emergency, preventing heavy objects from falling. 4. **Electrical System Inspection** - Check whether the power cord of the electric hoist has damage, aging, or leakage, and whether the plug and socket are in good contact. If there are any problems, replace or repair them in a timely manner. - Regularly clean the dust in the electrical control cabinet, and check whether the connections of various electrical components are firm, whether there are any loose or ablated phenomena, and whether the wire joints are overheated and discolored. - Check whether the limit switch of the electric hoist is working properly and whether the limit position is accurate. By manually operating the electric hoist to reach the upper and lower limit positions, check whether the limit switch can cut off the power in time and stop the operation of the electric hoist. Precautions for Repair 1. **Professional Maintenance Personnel** - The repair of the electric hoist should be carried out by maintenance personnel who have professional knowledge and skills and are familiar with the structure and principle of the electric hoist. The maintenance personnel should hold relevant electrician certificates or special equipment maintenance qualification certificates. 2. **Safety Measures** - Before repair, the power supply of the electric hoist must be cut off, and a warning sign saying "Do not switch on, someone is working" should be hung at the power switch to prevent accidental switch - on and potential safety accidents. - During repair, lower the heavy object of the electric hoist to the ground or take reliable support measures to prevent the heavy object from falling and injuring people. At the same time, ensure that there is sufficient space and good lighting conditions around the repair site. 3. **Use of Original Parts** - During repair, use original parts that match the model of the electric hoist or certified qualified substitutes. Do not use counterfeit, shoddy, or non - compliant parts to avoid affecting the performance and safety of the electric hoist. 4. **Repair Records** - Keep detailed records of the content of each repair, the replaced parts, the repair time, the maintenance personnel, etc., and establish a repair file. This is convenient for tracking the repair history and operating status of the electric hoist and providing a reference for subsequent maintenance and repair. 5. **Testing and Commissioning**

- After the repair is completed, conduct comprehensive testing and commissioning, including no - load operation, load testing, braking testing, limit testing, etc., to ensure that all performance indicators of the electric hoist meet the requirements. Only after normal operation can it be put into use.

RELATED PRODUCTS .

The polyester black lifting sling also features non-conductivity and no corrosion, ensuring safety and wide applicability. These characteristics make it an efficient and reliable hoisting tool, especi

The aircraft case truss hoist controller is suitable for the quick installation and adjustment of stage lighting, sound systems, and other equipment. It performs exceptionally well in enviro

Factory-direct hand-pulled stage hoists are ideal for the quick installation and adjustment of stage lighting, sound systems, and other equipment. They perform exceptionally well in environments witho

The stage truss motor equipped with a limit switch deeply integrates powerful performance, precise control, and excellent safety. It can not only easily handle the hoisting and accurate positioning of

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record