X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

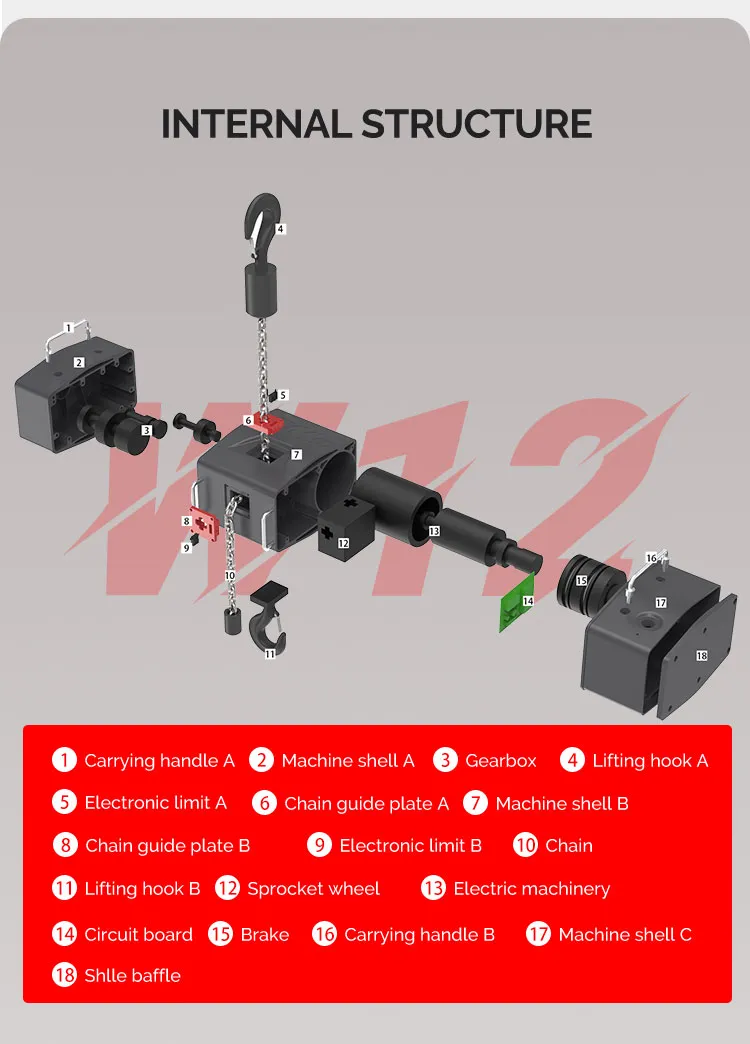

The W12 stage-specific electric hoist, also known as the self- hanging. It is mainly applicable to the construction of commercial stages, stage scenery, audio and lighting arrangements, as well as ban

Category : W12 Stage Electric Hoist

Get a Quote

Product Details

The inspection of the synchronization of stage electric hoists is of crucial importance, as it is related to the safety and effect of stage performances. The following are the specific methods for inspecting their synchronization in various aspects, including preparatory work, pre - operation inspection, in - operation monitoring, and post - operation review: Pre - inspection Preparatory Work - **Data Collection**: Obtain the equipment manuals, technical specification documents, and relevant installation drawings of the electric hoists, and get familiar with their technical parameters, working principles, and synchronization control methods. - **Tool Preparation**: Prepare the tools required for inspection, such as multimeters, laser rangefinders, dial indicators, wrenches, screwdrivers, etc., and ensure that the tools are complete and in normal working condition. - **Safety Measures**: Before inspection, the power supply must be cut off, and a "Do Not Close the Switch" sign should be hung at the power switch. At the same time, set up a safety warning line to ensure the safety of the inspectors. Static Inspection before Operation - **Mechanical Connection Inspection** - Carefully check each mechanical connection part of the electric hoist, including chains, wire ropes, pulleys, couplings, etc., to ensure that the connections are firm, without looseness, wear, deformation, or breakage, so as to avoid affecting synchronization due to mechanical component problems. - Check the installation brackets and fixing bolts of the electric hoist to ensure that the installation is firm, without looseness or displacement, and guarantee that non - synchronization will not occur during operation due to installation problems. - **Electrical System Inspection** - Use a multimeter to check the winding resistance of the motor. The three - phase resistance should be balanced, and the deviation should not exceed the specified value. Otherwise, it may lead to uneven motor output and affect synchronization. - Check the parameter settings of electrical equipment such as controllers and frequency converters to ensure that they are in line with the specifications of the electric hoist and the requirements of synchronization control, such as speed parameters, acceleration and deceleration times, etc. - Check whether the connections of the electrical circuits are correct and firm, without looseness, short - circuits, open - circuits, etc. Especially for the synchronization control circuit, ensure that the signal transmission is normal. Dynamic Inspection during Operation - **Jog Test** - Connect the power supply and perform jog operations to make the electric hoist rise and fall at a low speed. Observe whether the actions of each electric hoist are consistent, and check for any jamming, stagnation, or abnormal noises. - **Load Test** - After normal no - load operation, gradually increase the load and conduct operation tests under different loads. Generally, several stages such as 25%, 50%, 75%, and 100% of the rated load can be selected for testing. - During the load operation, use tools such as laser rangefinders or dial indicators to measure the lifting height or displacement of each electric hoist, and compare the differences between them. Generally, the synchronization error should be controlled within the specified range, such as ±5mm. - **Speed Monitoring** - A tachometer or other speed monitoring equipment can be used to measure the rotational speed of the motor of each electric hoist to ensure that their speeds are basically the same during operation, and the speed deviation should be within the allowable range. Review after Operation - **Shutdown Inspection** - After the operation is completed, cut off the power supply and check the mechanical connection parts and electrical system again. Check for any looseness, heating, wear, etc. caused by the operation, as these may all affect synchronization. - **Data Analysis**

- Analyze the data recorded during the inspection process, such as the differences in lifting height and speed deviation, to evaluate whether the synchronization performance of the electric hoist meets the requirements.

RELATED PRODUCTS .

The polyester black lifting sling also features non-conductivity and no corrosion, ensuring safety and wide applicability. These characteristics make it an efficient and reliable hoisting tool, especi

The aircraft case truss hoist controller is suitable for the quick installation and adjustment of stage lighting, sound systems, and other equipment. It performs exceptionally well in enviro

Factory-direct hand-pulled stage hoists are ideal for the quick installation and adjustment of stage lighting, sound systems, and other equipment. They perform exceptionally well in environments witho

The stage truss motor equipped with a limit switch deeply integrates powerful performance, precise control, and excellent safety. It can not only easily handle the hoisting and accurate positioning of

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record