X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

Stage electric hoists are valuable aids in building stage scenes and presenting performances. They play a crucial role in various settings, such as theaters, concerts, opera houses, dance venues, and

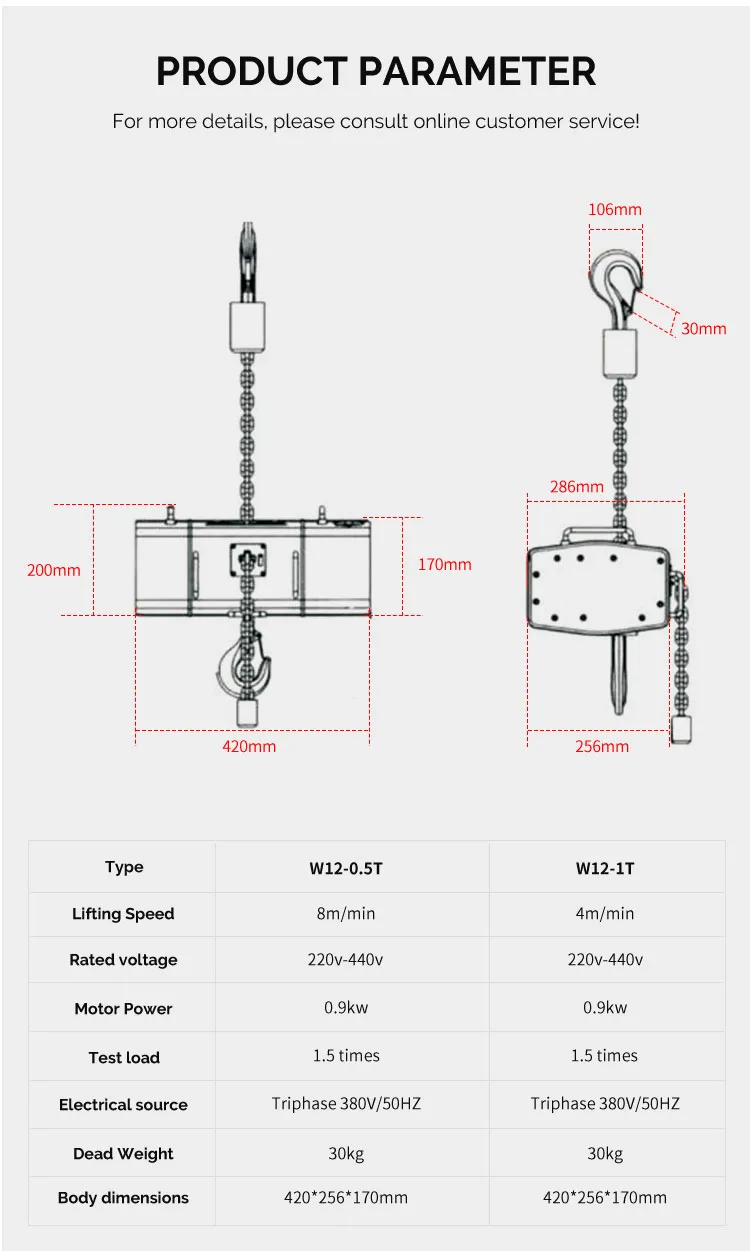

Category : W12 Stage Electric Hoist

Get a Quote

Product Details

Product Name: W12 Stage Electric Hoist

Product Type: Stage Electric Hoist

Product Description: Tianjin Kemei Machinery Manufacturing Co., Ltd. is a modern production - oriented enterprise integrating independent R & D, manufacturing, and sales. Located in the beautiful coastal city of Tianjin, it enjoys a unique geographical location, convenient transportation, and smooth logistics. The company is committed to the development and manufacturing of stage entertainment lifting products. Its main products include stage - specific endless chain electric hoists, stage - specific hand chain hoists, black lifting slings, group control boxes, rail grippers, and auxiliary products, etc. These products are widely used in the fields of truss construction for concerts, conference halls, exhibition hall, high - end customized weddings, and various celebration performances.

Product Specifications: 1. Double - brake system ensures the safety of the product and the accuracy of braking. When in synchronous control, the error is minimized. 2. The protection level reaches IP56, with a waterproof design, and it has passed the tests of rain and water immersion. 3. The product is equipped with upper and lower limit switches and adjustable limit blocks. 4. The whole machine shell is made of aviation aluminum, making the body more lightweight. There are many precautions for the daily inspection and use of stage electric hoists. The following is an introduction from the two aspects of daily inspection and usage precautions: Precautions for Daily Inspection 1. Appearance Inspection: Check whether the shell of the electric hoist has cracks, deformations, or damage. Especially after collisions or long - term use, pay special attention to key parts such as the motor shell and the reducer shell. 2. Check whether the chain has rust, wear, deformation, or elongation of the chain pitch. When the chain wear exceeds the specified range, it should be replaced in a timely manner to ensure safety. 3. Check whether the hook is deformed, cracked, whether the surface is smooth, and whether the rotation and locking devices of the hook are flexible and reliable. Electrical System Inspection 1. Check whether the power cord is damaged, aged, or exposed, and whether the plug and socket are in good contact, without signs of looseness or overheating. 2. Check whether the control buttons are sensitive. After pressing the buttons, the electric hoist should be able to accurately perform operations such as lifting, lowering, and stopping, without jamming or misoperation. Check whether the motor wiring is firm, and whether there are abnormal conditions such as overheating and strange odors. The insulation performance of the motor should also be tested regularly to prevent electric leakage accidents. Brake System Inspection 1. Check whether the brake pads of the brake are severely worn. If the wear of the brake pads exceeds the specified thickness, it will affect the braking effect and needs to be replaced in a timely manner. 2. Test the braking performance of the brake. Conduct braking tests under no - load and loaded conditions respectively to ensure that the electric hoist can brake quickly and reliably when stopping, without slipping. 3. Check whether the brake spring has good elasticity, and whether there are problems such as deformation and breakage. The elasticity of the spring is directly related to the braking torque of the brake. Transmission System Inspection 1. Check whether the oil level of the reducer is normal and the oil quality is good. If the oil deteriorates, contains impurities, or the oil level is too low, the lubricating oil should be replaced or replenished in a timely manner. 2. Listen for any abnormal noise from the transmission components during the operation of the electric hoist, such as whether the gear meshing is smooth and the chain transmission is smooth. If there is abnormal noise, it may indicate that there are problems such as wear and looseness of the transmission components. 3. Check whether the bolts at each connection part are tightened, especially at the connection parts of the motor and the reducer, and the reducer and the chain wheel, to prevent components from falling off or unstable transmission due to loose bolts. Usage Precautions 1. Operating Specifications: Operators must undergo professional training, be familiar with the operation methods and safety precautions of the electric hoist, and operate strictly in accordance with the operating procedures. When operating, concentrate and closely observe the operation of the electric hoist. If any abnormalities are found, stop the operation immediately and conduct inspections. When multiple people cooperate in the operation, clarify the command signals to ensure that the signals are clear and accurate. Operators should follow the commands and not operate without permission. 2. Load Requirements: - Overloading is strictly prohibited. The appropriate load must be selected according to the rated lifting capacity of the electric hoist. Before lifting, accurately understand the weight of the item to be lifted. - The lifted items should be evenly distributed, and the center of gravity should be stable. Avoid situations such as uneven loading and diagonal pulling to prevent danger caused by uneven stress on the electric hoist. 3. Operating Environment: - Check whether the running track is flat, smooth, and free of obstacles or deformations to ensure that the electric hoist can run smoothly on the track. - The stage electric hoist should be used within the specified environmental temperature and humidity range, and avoid long - term use in harsh environments such as high temperatures, humidity, and corrosive gases. - During the lifting and running process, ensure that there are no people or obstacles around, and set up necessary safety warning areas to prevent personal injury and equipment damage caused by falling items or collisions of the electric hoist. 4. Maintenance: - Regularly clean the electric hoist, remove dust, oil stains, and other debris on the surface to keep the equipment clean. - According to the requirements of the equipment operation manual, regularly lubricate the electric hoist, lubricating parts such as chains, gears, and bearings to reduce wear and extend the service life of the equipment.

- For electric hoists that have been out of use for a long time, conduct a comprehensive inspection and trial operation before reuse, and put them into use only after confirming that there are no problems.

RELATED PRODUCTS .

The polyester black lifting sling also features non-conductivity and no corrosion, ensuring safety and wide applicability. These characteristics make it an efficient and reliable hoisting tool, especi

The aircraft case truss hoist controller is suitable for the quick installation and adjustment of stage lighting, sound systems, and other equipment. It performs exceptionally well in enviro

Factory-direct hand-pulled stage hoists are ideal for the quick installation and adjustment of stage lighting, sound systems, and other equipment. They perform exceptionally well in environments witho

The stage truss motor equipped with a limit switch deeply integrates powerful performance, precise control, and excellent safety. It can not only easily handle the hoisting and accurate positioning of

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record