X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

The W12 stage-specific electric hoist, also known as the self- hanging. It is mainly applicable to the construction of commercial stages, stage scenery, audio and lighting arrangements, as well as ban

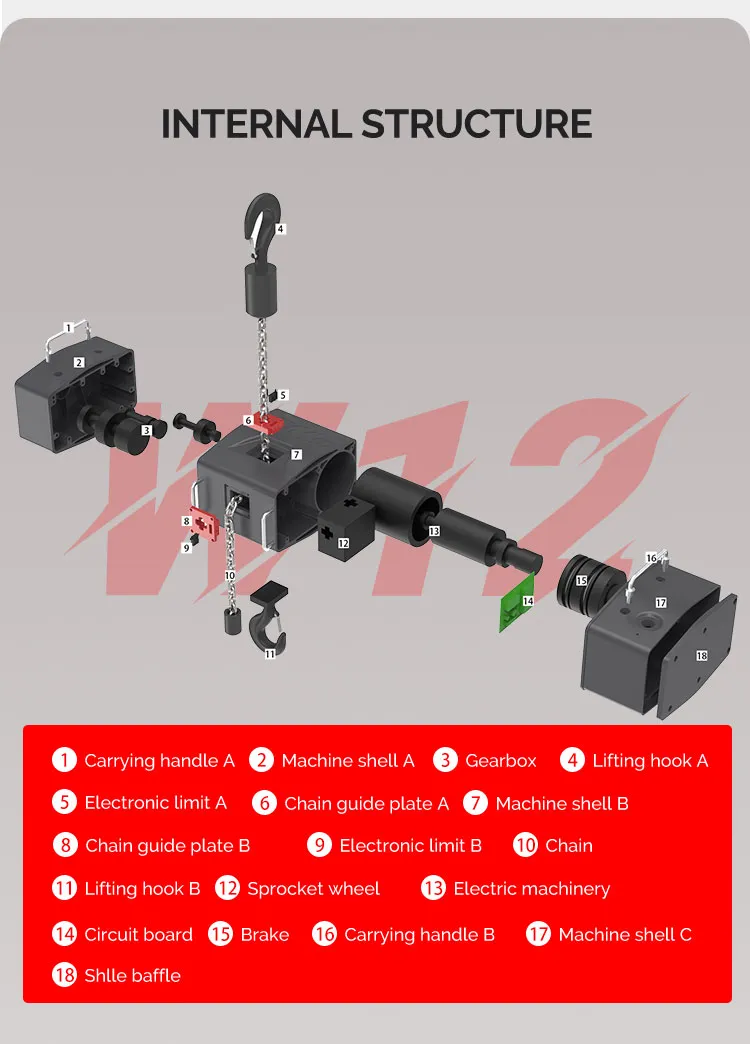

Category : W12 Stage Electric Hoist

Get a Quote

Product Details

There are many precautions for the installation of stage electric hoists. The following is an introduction from three stages: before installation, during installation, and after installation.

Before Installation

- **Check the integrity of the equipment**: Carefully inspect all components of the electric hoist, including the motor, reducer, chain, hook, limit switch, etc., to ensure there is no damage, deformation, or missing parts. At the same time, check whether there are product qualification certificates and relevant technical documents. - **Confirm the installation location**: Determine the installation location of the electric hoist according to the structure of the stage and usage requirements. Consider the even distribution of the load, avoid installing it at weak structural points. Also, ensure there is enough safe distance from surrounding objects for easy operation and maintenance. Generally, leave at least 0.5 meters of space on both sides. - **Inspect the installation foundation**: The installation foundation must be firm and reliable, capable of withstanding the weight of the fully - loaded electric hoist and the dynamic load generated during operation. For installations on the ceiling or truss, check the strength and stability of the ceiling or truss, and reinforce it if necessary. - **Prepare installation tools and materials**: Prepare the required installation tools, such as wrenches, screwdrivers, electric drills, cranes, etc., as well as the materials needed for installation, such as bolts, nuts, washers, wire ropes, etc. Ensure that the specifications and quality of the tools and materials meet the requirements.

During Installation

- **Ensure horizontal and vertical accuracy**: When installing the electric hoist, use tools such as a spirit level and plumb line to ensure that the electric hoist is installed horizontally and its running track is vertical. The deviation should be controlled within the specified range. Generally, the horizontal deviation does not exceed five - thousandths, and the vertical deviation does not exceed two - thousandths.

- **Connect the power supply correctly**: Connect the appropriate power supply according to the rated voltage and power requirements of the electric hoist. The wiring should be firm and reliable to avoid loosening, short - circuiting, etc. Install a grounding device to ensure electrical safety. The grounding resistance is generally not more than 4 ohms. - **Install the limit switch**: The limit switch is an important device to ensure the safe operation of the electric hoist. Install and debug it accurately. Ensure that the positions of the upper and lower limit switches are set reasonably. When the hook rises or falls to the limit position, the limit switch can cut off the power supply in a timely manner and stop the operation of the electric hoist. - **Install the chain or wire rope**: If it is a chain - type electric hoist, ensure that the chain is installed correctly without twisting or knotting. The tightness of the chain should be appropriate. Generally, when unloaded, the sag of the chain does not exceed 2% of the distance between two chain links. If it is a wire - rope - type electric hoist, check whether the specifications and models of the wire rope meet the requirements. Pay attention to the winding direction and number of layers of the wire rope during installation to avoid the phenomenon of rope tangling.

After Installation

- **Debug and run**: After installation, conduct an unloaded debugging run to check whether the operation of the electric hoist is stable and whether there are any abnormal noises, vibrations, etc. Then carry out a loaded debugging, gradually increasing the load, and check the operation of the electric hoist under different loads, as well as the reliability of the limit switch, braking device, etc. - **Check the braking performance**: The braking device is the key to the safe operation of the electric hoist. After installation, focus on checking its braking performance. Conduct braking tests under unloaded and loaded conditions respectively, and measure the braking distance. Generally, the braking distance should not exceed 1/1000 of the rated lifting speed.

- **Do a good job in protection and labeling**: Install protective devices for the electrical parts and moving parts of the electric hoist. For example, the electrical box door should be closed tightly to prevent electric shock; install protective covers for moving parts such as chains and gears to prevent injury from human contact. At the same time, post safety warning signs and operation instructions at obvious parts such as the body of the electric hoist and the operation position to remind operators of safety precautions.

RELATED PRODUCTS .

The polyester black lifting sling also features non-conductivity and no corrosion, ensuring safety and wide applicability. These characteristics make it an efficient and reliable hoisting tool, especi

The aircraft case truss hoist controller is suitable for the quick installation and adjustment of stage lighting, sound systems, and other equipment. It performs exceptionally well in enviro

Factory-direct hand-pulled stage hoists are ideal for the quick installation and adjustment of stage lighting, sound systems, and other equipment. They perform exceptionally well in environments witho

The stage truss motor equipped with a limit switch deeply integrates powerful performance, precise control, and excellent safety. It can not only easily handle the hoisting and accurate positioning of

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record