X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

Professional installation team: The installation of the stage electric hoist must be carried out by professional technicians. They have rich experience and professional knowledge, which can ensure the

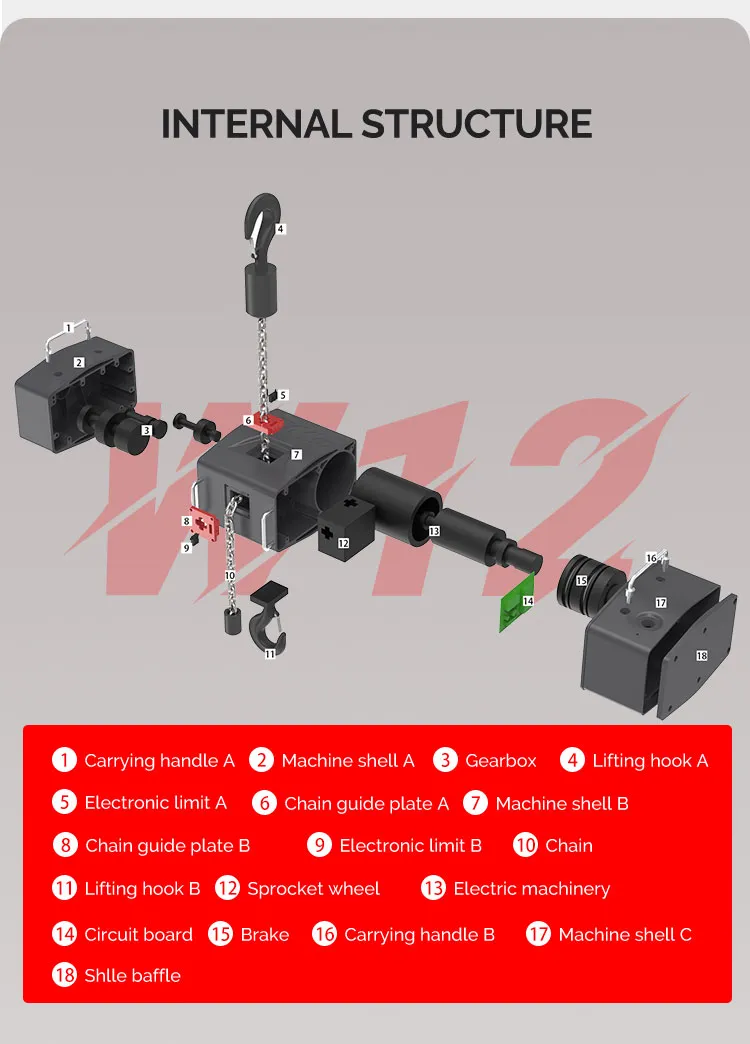

Category : W12 Stage Electric Hoist

Get a Quote

Product Details

Safety precautions for stage electric hoist

1、 Caution is required during the installation process

Professional installation team: The installation of the stage electric hoist must be carried out by professional technicians. They have rich experience and professional knowledge, which can ensure the accuracy of the installation process and lay the foundation for subsequent safe use.

Installation environment assessment: Before installation, a comprehensive assessment of the structure and environment of the stage should be conducted. Ensure that the installation location can withstand the weight of the electric hoist and the pulling force generated during operation, while ensuring that there are no obstacles around that affect the normal operation of the hoist.

Secure fixation: During installation, ensure that the electric hoist is firmly connected to the supporting structure. Use connectors that meet the standards and strictly follow the installation instructions to prevent loosening or detachment.

2、 Carefully check before use

Appearance inspection: Check whether the shell of the electric hoist is damaged or deformed, and whether the hook has cracks, wear, and other conditions. Any appearance defect may affect the safety performance of the device.

Wire rope inspection: Carefully inspect the wire rope for broken wires, wear, twisting, and other issues. Steel wire rope is a critical component for carrying heavy objects and must be ensured to be in good condition.

Braking system testing: The braking system is an important device for ensuring safety. Before use, the braking system should be tested to ensure that it can brake quickly and effectively, preventing accidental falls of heavy objects.

Electrical system inspection: Check if the electrical connections are secure and if the wires are damaged. Ensure the normal operation of the electrical system and avoid safety accidents caused by electrical failures.

3、 Strict and standardized operation process

Follow the operating procedures: Operators must be familiar with the operating procedures of the stage electric hoist and strictly follow the procedures for operation. Do not engage in illegal operations, such as overloading or pulling heavy objects diagonally.

Control lifting speed: When lifting heavy objects, the lifting speed should be steadily controlled to avoid excessive speed causing the object to shake and increasing safety risks. At the same time, it is also important to avoid sudden stops to prevent impact on equipment and heavy objects.

Stay focused and observe: During the operation, the operator should always stay focused and observe the operation status of the electric hoist, the suspension of heavy objects, and changes in the surrounding environment. Once an abnormality is detected, the operation should be stopped immediately and checked.

Collaboration and cooperation among multiple people: In some large-scale stage constructions, it may be necessary for multiple people to work together to operate the electric hoist. At this point, it is important to ensure smooth communication and tacit cooperation among team members to avoid safety accidents caused by uncoordinated operations.

4、 Daily maintenance cannot be ignored

Regular cleaning: Regularly clean the stage electric hoist to remove dust, oil stains, and other debris from the surface, preventing them from entering the equipment and affecting its normal operation.

Lubrication and maintenance: According to the maintenance requirements of the equipment, regularly lubricate key components such as gears, bearings, wire ropes, etc., to ensure smooth operation of the equipment and reduce wear and tear.

Inspection and maintenance: Conduct regular comprehensive inspections to promptly identify and eliminate potential faults and safety hazards. For faulty components, they should be repaired or replaced in a timely manner and should not be operated with defects.

RELATED PRODUCTS .

The electric hoist for stage audio equipment is a professional hoisting device made of high-strength lightweight alloy with an integrated compact structure. Its rated load capacity is precisely matche

The stage show hoist controller is a core control device that integrates safety protection command transmission functions such as limit protection and overload protection, used to accurately control t

The truss-specialized electric winch is a hoisting device equipped with precise limit and overload protection, specially designed for the lifting and shifting operations of stage trusses.

The control of lifting speed of high-quality manual chain hoists is directly related to the type of load borne by the chain, and is an important factor affecting the service life of the chain. During

2025-11-05

创始人

0

GET show Guangzhou International Performing Arts E...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2025-11-05

创始人

0

Guangzhou International Performing Arts Equipment ...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-05-27

创始人

0

Guangzhou International Professional Lighting and ...

We look forward to meeting you at the exhibition site and jointly drawing a new blueprint for industry development!

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...