X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

In stage performances, stage electric hoists play a crucial role. However, due to various reasons, the stage electric hoist may malfunction. Timely troubleshooting and adopting effective solutions are

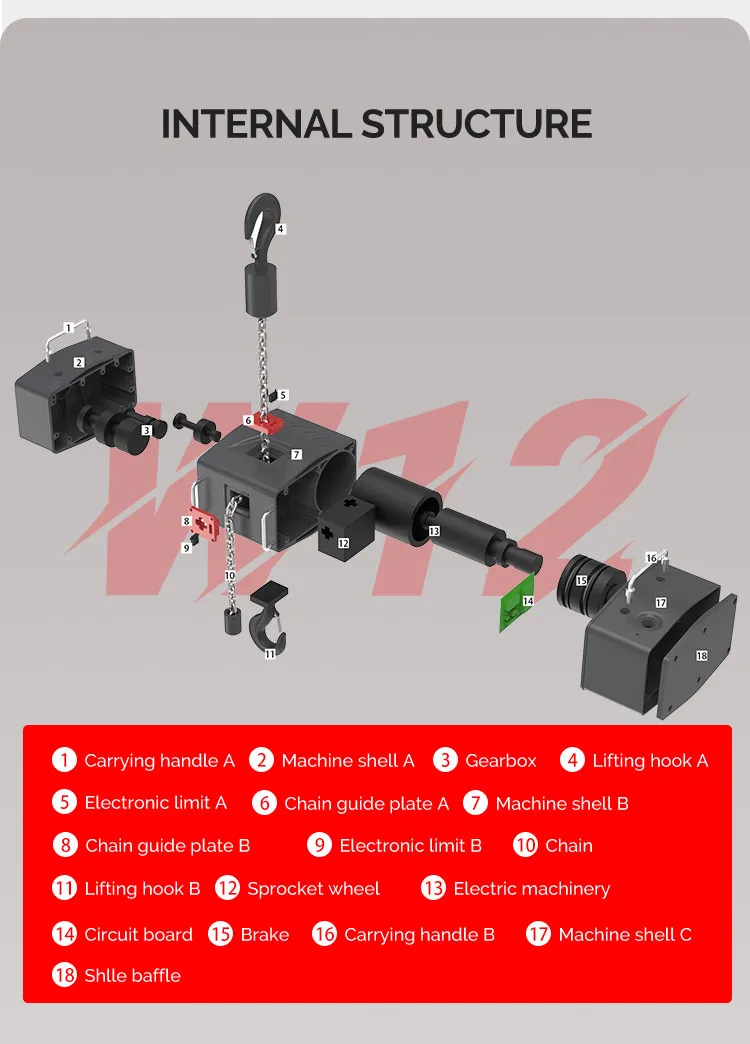

Category : W12 Stage Electric Hoist

Get a Quote

Product Details

Troubleshooting of Stage Electric Gourd

In stage performances, stage electric hoists play a crucial role. However, due to various reasons, the stage electric hoist may malfunction. Timely troubleshooting and adopting effective solutions are crucial for ensuring the smooth progress of stage performances. This article will introduce the troubleshooting and troubleshooting of common faults in stage electric hoists

1. The motor is not running

Check if the power supply is connected properly. Check if the power cord is loose or damaged, and if the plug is securely plugged in. Ensure that the power supply voltage meets the requirements of the electric hoist.

Check if the control buttons are functioning properly. When pressing the control button, observe whether there is a signal transmitted to the motor. If the control button is damaged, a new button needs to be replaced.

Check if the motor is damaged. A multimeter can be used to measure the resistance value of the motor and determine whether there is a short circuit or open circuit in the motor. If the motor is damaged, it is necessary to contact professional maintenance personnel for repair or replacement.

2. Weak lifting or slow speed

Check if the load exceeds the rated load of the electric hoist. If overloaded, the load should be reduced to the rated range.

Check if the steel wire rope is tangled or severely worn. If the steel wire rope is tangled haphazardly, it should be reorganized; If the steel wire rope is severely worn, it should be replaced in a timely manner.

Check if there is a malfunction in the motor. If the motor speed drops or heats up, it may be due to internal problems and requires maintenance.

3. Brake failure

Check if the brake pads are severely worn. If the brake pads are excessively worn, they should be replaced in a timely manner.

Check if the brake spring is loose or damaged. If the brake spring is loose or damaged, it should be adjusted or replaced.

Check for oil stains or debris between the brake wheels and brake pads. If there is oil or debris, it should be cleaned thoroughly to ensure that the friction between the brake wheel and the brake pad is normal.

4. Excessive noise

Check if there is a malfunction in the motor. Motor failure may cause excessive noise, such as bearing damage, rotor imbalance, etc. The motor needs to be inspected or replaced.

Check if the transmission components are severely worn. Transmission components such as gears and sprockets are severely worn and can produce noise. Worn transmission components should be replaced promptly.

Check if the steel wire rope is rubbing against other components. If the steel wire rope rubs against other components, the position of the steel wire rope should be adjusted to avoid friction.

RELATED PRODUCTS .

Stage Electric Hoist Controller for Concert is an intelligent core electrical control device specially designed for concerts and large-scale performances.It is mainly used for the start-stop, lifting,

Heavy Duty Stage Lifting Sling is a high-load-bearing flexible lifting sling specially designed for stage high-altitude operation and large equipment hoisting. Made of high-strength polyester fiber wi

Wholesale Stage Hand Chain Hoist is a special manual lifting equipment for stages supplied in bulk by original factories to foreign traders, engineering contractors, distributors and other customers.

Chinese Factory Stage Electric Hoist refers to the stage electric hoist produced by professional manufacturers in China, featuring direct factory supply, mature production technology, strict quality c

2025-11-05

创始人

0

GET show Guangzhou International Performing Arts E...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2025-11-05

创始人

0

Guangzhou International Performing Arts Equipment ...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-05-27

创始人

0

Guangzhou International Professional Lighting and ...

We look forward to meeting you at the exhibition site and jointly drawing a new blueprint for industry development!

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...