X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

In stage equipment, the stage electric hoist plays a crucial role. To ensure its safe and reliable operation, trial operation is an essential step. However, during the trial operation of the stage e

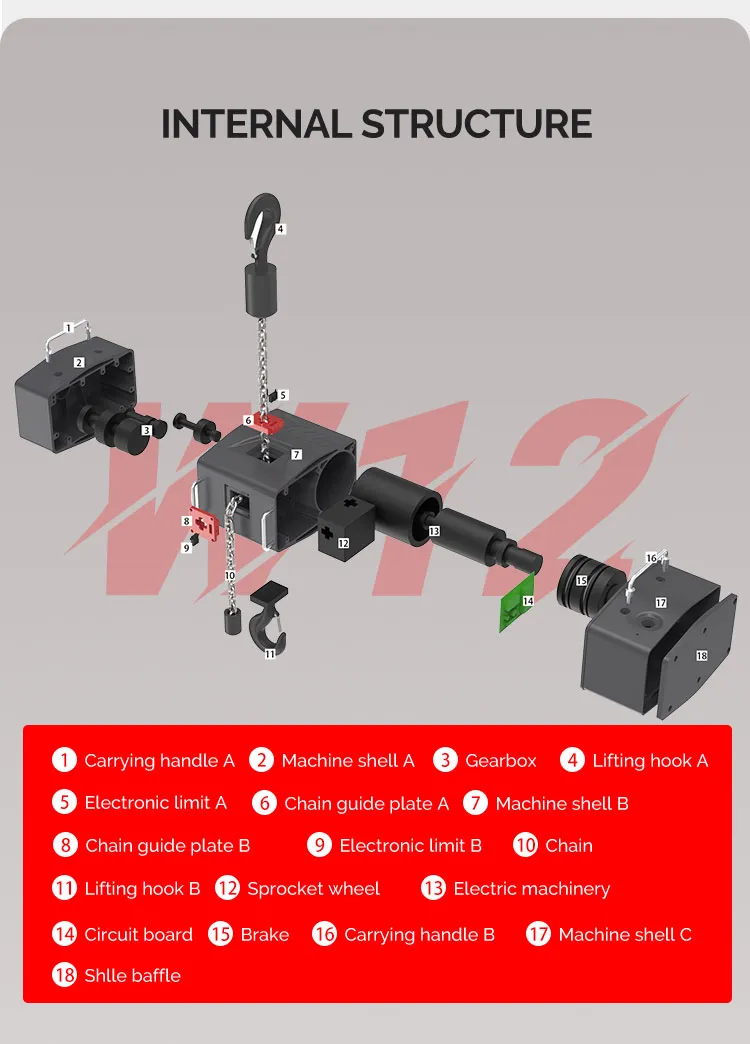

Category : W12 Stage Electric Hoist

Get a Quote

Product Details

Precautions for the operation and trial load of stage electric hoist

1、 Preparation work before trial load

(1) Check the appearance of the electric hoist

Before conducting the test load, the appearance of the electric hoist should be checked for any damage, deformation, or cracks. At the same time, it is necessary to check for wear, cracks, or deformation in components such as hooks, chains, and wire ropes. If any problems are found, they should be repaired or replaced in a timely manner.

(2) Check the electrical system of the electric hoist

Check if the electrical system of the electric hoist is functioning properly, including power cords, plugs, switches, controllers, and other components. Ensure that the electrical system is free from short circuits, open circuits, leakage, and other issues. If any problems are found in the electrical system, they should be repaired or replaced in a timely manner.

(3) Choose a suitable test load

Select a suitable test load based on the rated load of the electric hoist. The weight of the test load should gradually increase to simulate different load situations in actual use. At the same time, the center of gravity of the test load should be on the same vertical line as the hook of the electric hoist to ensure the accuracy and safety of the test load.

(4) Determine the testing site

Choose a flat, solid, and obstacle free site for trial loading. The testing site should be spacious enough to ensure that the electric hoist has enough space to operate during the testing process. At the same time, the test loading site should be kept away from crowds and flammable and explosive materials to ensure the safety of the test loading.

2、 Precautions during the trial load process

(1) Requirements for Operators

During the trial load process, operators must undergo professional training and be familiar with the operation methods and safety precautions of electric hoists. Operators should wear necessary personal protective equipment, such as helmets, seat belts, gloves, etc. At the same time, operators should remain focused and not leave their operating positions without authorization.

(2) Steps and methods for trial loading

The trial load should be carried out in the order of empty load, light load, and then heavy load. During the trial load process, the weight of the trial load should be gradually increased, and the increase in weight each time should not be too large. At the same time, attention should be paid to observing the operation of the electric hoist, including lifting speed, descent speed, braking performance, noise, etc. If any abnormal situation is found during the test load of the electric hoist, the test load should be stopped immediately, and inspection and maintenance should be carried out.

(3) Safety protection measures

During the trial load process, necessary safety protection measures should be set up, such as warning lines, warning signs, etc. At the same time, a dedicated person should be arranged to be responsible for on-site safety supervision to ensure safety during the trial load process. If an unexpected situation occurs during the trial load process, the emergency plan should be immediately activated for emergency rescue.

3、 Inspection and maintenance after trial load

(1) Check the performance of the electric hoist

After the test load is completed, the performance of the electric hoist should be checked for normality, including lifting speed, descent speed, braking performance, noise, etc. If it is found that the performance of the electric hoist has decreased or abnormal conditions during the trial load process, it should be inspected and repaired in a timely manner.

(2) Check the components of the electric hoist

After the trial load is completed, the components of the electric hoist should be checked for damage, deformation, or wear. At the same time, components such as hooks, chains, and wire ropes should be inspected for cracks, deformations, or wear. If any problems are found with the components of the electric hoist, they should be repaired or replaced in a timely manner.

(3) Maintenance and upkeep of electric hoist

After the trial load is completed, the electric hoist should be maintained and serviced, including cleaning, lubrication, fastening, etc. At the same time, electric hoists should be regularly inspected and maintained to ensure their stable performance, safety, and reliability.

RELATED PRODUCTS .

The polyester black lifting sling also features non-conductivity and no corrosion, ensuring safety and wide applicability. These characteristics make it an efficient and reliable hoisting tool, especi

The aircraft case truss hoist controller is suitable for the quick installation and adjustment of stage lighting, sound systems, and other equipment. It performs exceptionally well in enviro

Factory-direct hand-pulled stage hoists are ideal for the quick installation and adjustment of stage lighting, sound systems, and other equipment. They perform exceptionally well in environments witho

The stage truss motor equipped with a limit switch deeply integrates powerful performance, precise control, and excellent safety. It can not only easily handle the hoisting and accurate positioning of

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record