X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

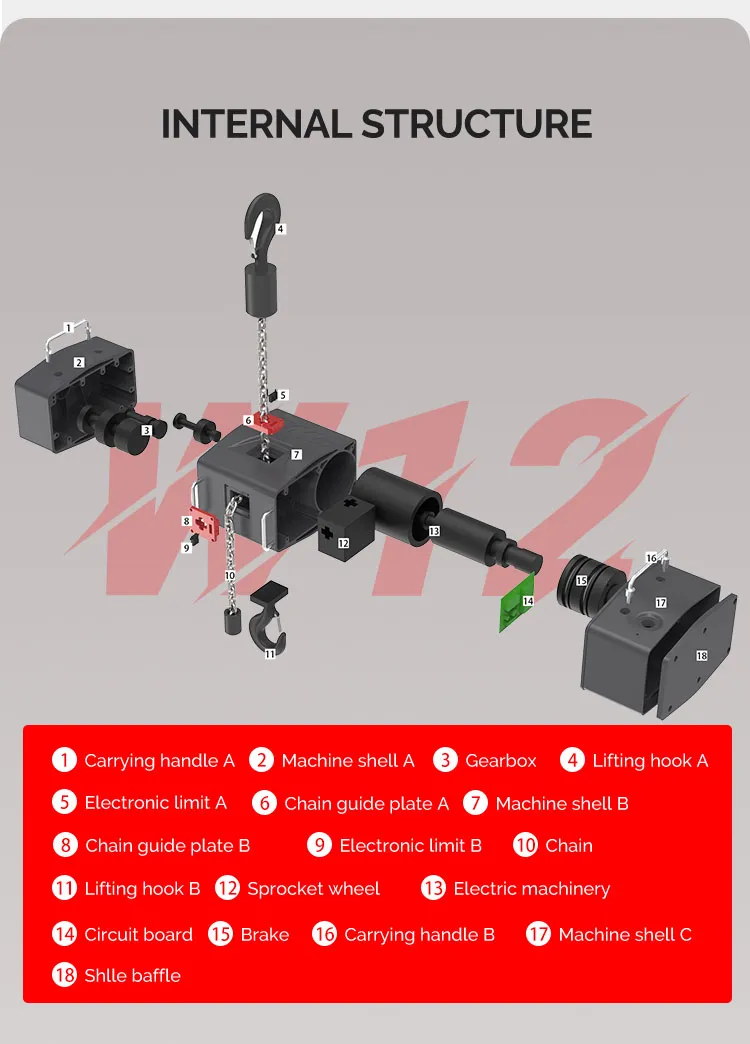

The W12 stage-specific electric hoist, also known as the self- hanging. It is mainly applicable to the construction of commercial stages, stage scenery, audio and lighting arrangements, as well as ban

Category : W12 Stage Electric Hoist

Get a Quote

Product Details

To ensure the safety of stage electric hoists during anti - entanglement tests, measures can be taken in aspects such as pre - test preparation, test process control, and post - test inspection. The details are as follows: Pre - test Preparation - Equipment Inspection - Conduct a comprehensive inspection of the mechanical components of the electric hoist, such as the motor, reducer, brake, drum, wire rope or chain, etc., to ensure there are no defects such as wear, cracks, or deformation. Ensure that all components are firmly connected and well - lubricated. - Check the electrical system, including motor wiring, controller, limit switch, overload protection device, etc., to ensure correct electrical connections, no potential safety hazards such as electric leakage or short - circuit, and normal operation of all electrical components. - Inspection and Calibration of Safety Devices - Focus on inspecting the anti - entanglement devices, such as rope guides, rope arranging devices, etc., to ensure they are correctly installed, sensitive and reliable in operation, and can effectively guide the wire rope or chain to be neatly arranged to prevent entanglement. - Calibrate the limit switch of the electric hoist to ensure it can accurately operate within the specified stroke range, preventing the electric hoist from exceeding the limit position and causing safety accidents. At the same time, check the overload protection device to ensure that it can cut off the power supply in a timely manner when the load exceeds the rated value, protecting the safety of equipment and personnel. - Test Environment Inspection - Clean up the test site to ensure there are no sundries or obstacles around, and keep the passage unobstructed so that personnel can avoid and operate in a timely manner during the test. - Check the ground bearing capacity of the test site to ensure it can bear the weight of the electric hoist and the test load, preventing ground subsidence or deformation from affecting the test safety. - Ensure that the test site has good lighting conditions, facilitating the operator to observe the operating status and entanglement of the electric hoist. Safety Control during the Test Process - Personnel Allocation and Training - Arrange professional technicians to conduct the test operation. The operators should be familiar with the performance, operation methods, and safety precautions of the electric hoist, and have the ability to respond to unexpected situations. - Assign safety supervisors on - site to supervise the test process, promptly correct the non - standard behaviors of the operators, and ensure that the test is carried out in accordance with safety regulations. - Load Control - Load the test according to the test plan strictly. Start from no - load and gradually increase the load to the rated load or even an appropriate overload situation. The loading process should be stable to avoid impacts caused by sudden loading or unloading. - During the load test, closely observe the operating status of the electric hoist, including motor current, sound, temperature, etc., as well as the winding situation of the wire rope or chain. If there is any abnormality, immediately stop the test, find out the cause, and continue after troubleshooting. - Safety Operation Specifications - During the test, the operator should stand in a safe position, away from the moving parts of the electric hoist and areas where danger may occur, such as the swing range of the wire rope or chain, and under the heavy object. - It is strictly prohibited to manually interfere with the winding of the wire rope or chain during the operation of the electric hoist. If adjustment is needed, the operation of the electric hoist must be stopped first. - Before each lifting or lowering operation, confirm the safety of the surrounding personnel and issue a warning signal. Post - test Safety Inspection and Summary - Equipment Inspection and Maintenance - After the test, inspect the electric hoist again to check whether there are new wear, deformation, or damage to each component caused by the test, especially at key positions such as the fixed end and connection parts of the wire rope or chain. - Record and analyze the problems found during the test, and promptly maintain and service the equipment, replace the damaged parts, and ensure that the equipment returns to a normal state. - Data Organization and Reporting - Organize various data during the test, including load conditions, operating parameters, the action of the anti - entanglement device, etc., evaluate the test results, and determine whether the anti - entanglement performance of the electric hoist meets the requirements.

- Write a detailed test report, recording the test process, problems found and their handling, test conclusions, etc., providing a reference for the subsequent use and maintenance of the equipment.

In addition to the above measures, the safety of stage electric hoists during anti - entanglement tests can also be ensured from aspects such as adding auxiliary protection, strengthening monitoring and emergency response. The specific methods are as follows: Adding Auxiliary Protection and Safety Devices - Install anti - derailment devices: Install anti - derailment devices on the edge of the drum or the running track of the wire rope to prevent the wire rope from jumping out of the drum or pulley, avoiding entanglement and other safety accidents caused by the wire rope jumping out. - Set up dual - limit protection: In addition to the conventional upper and lower limit switches, install an additional set of standby limit switches or use a controller with dual - limit function. When the main limit switch fails, the standby limit switch can come into play in a timely manner to prevent the electric hoist from exceeding the safe travel. - Equip with safety locking devices: Install safety locking devices at key parts of the electric hoist, such as the drum shaft or the drive mechanism. Before the test and when a pause is needed during the test, the electric hoist can be locked through the safety locking device to prevent it from starting accidentally or rotating due to external forces, which could lead to the entanglement of the wire rope or chain. Applying Monitoring and Detection Technologies - Install a video monitoring system: Install multiple high - definition cameras around the electric hoist and at key positions of the test site to monitor the entire test process of the electric hoist in real - time. Operators can observe the operating status of the electric hoist, the winding situation of the wire rope or chain, and changes in the surrounding environment comprehensively through the monitoring screen, and discover potential safety hazards in a timely manner. - Adopt sensor monitoring: Use tension sensors to monitor the tension changes of the wire rope or chain. Once abnormal fluctuations in tension occur, it may indicate the existence of entanglement or other faults, and the system will immediately issue an alarm. In addition, temperature sensors can be installed to monitor the temperature of components such as the motor and reducer, preventing safety accidents caused by excessive temperature due to overload or faults. - Introduce an intelligent anti - entanglement system: Apply an intelligent anti - entanglement system based on artificial intelligence and image recognition technology. This system can analyze the images captured by the cameras in real - time, automatically identify the winding state of the wire rope or chain. Once a winding trend or abnormal situation is detected, it can quickly issue an instruction to stop the operation of the electric hoist and give corresponding alarm information. Strengthening Safety Management and System Construction - Formulate a detailed emergency plan: For various potential safety accidents during the test, such as wire rope breakage, electric hoist fall, severe entanglement, etc., formulate a detailed and highly operable emergency plan. Clearly define the emergency measures to be taken, the evacuation routes for personnel, the rescue methods, and the division of responsibilities of each person in case of an accident, and regularly organize relevant personnel to conduct emergency drills to ensure a rapid and effective response in case of emergencies. - Establish a safety inspection and re - inspection system: Arrange different professionals to conduct multiple safety inspections and re - inspections before, during, and after the test. The pre - test inspection focuses on the initial state of the equipment and the environment, the inspection during the test mainly pays attention to the equipment operation and the standardization of personnel operations, and the post - test re - inspection focuses on checking whether the equipment has been damaged or has abnormal changes. Through multiple inspections to confirm each other, ensure that safety measures are effectively implemented. - Strengthen safety training and education: In addition to providing professional skill training to operators, also strengthen the safety awareness education of all personnel participating in the test. Regularly organize safety training courses to explain the safety operation procedures of stage electric hoists, the importance of anti - entanglement tests, and the analysis of safety accident cases, etc., to improve the attention and response ability of all personnel to safety issues.

RELATED PRODUCTS .

The flexible lifting sling is a kind of lifting tool used in lifting operations. It is usually made of high-strength fiber materials or metal ropes with a flexible outer layer. It has the characterist

The truss hoist controller, relying on its precise algorithm, can synchronously and accurately manipulate dozens of hoists to lift and lower in coordination. It makes the stage mechanical devices coop

The manual stage chain hoist is easy to operate. Even volunteers who are new to stage equipment can quickly get the hang of it and complete the lifting and lowering work of small props.

Advanced stage winches usually utilize electric motors or hydraulic systems to provide power, and achieve the lifting, lowering, and positioning of heavy objects through a series of mechanical transmi

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record