X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

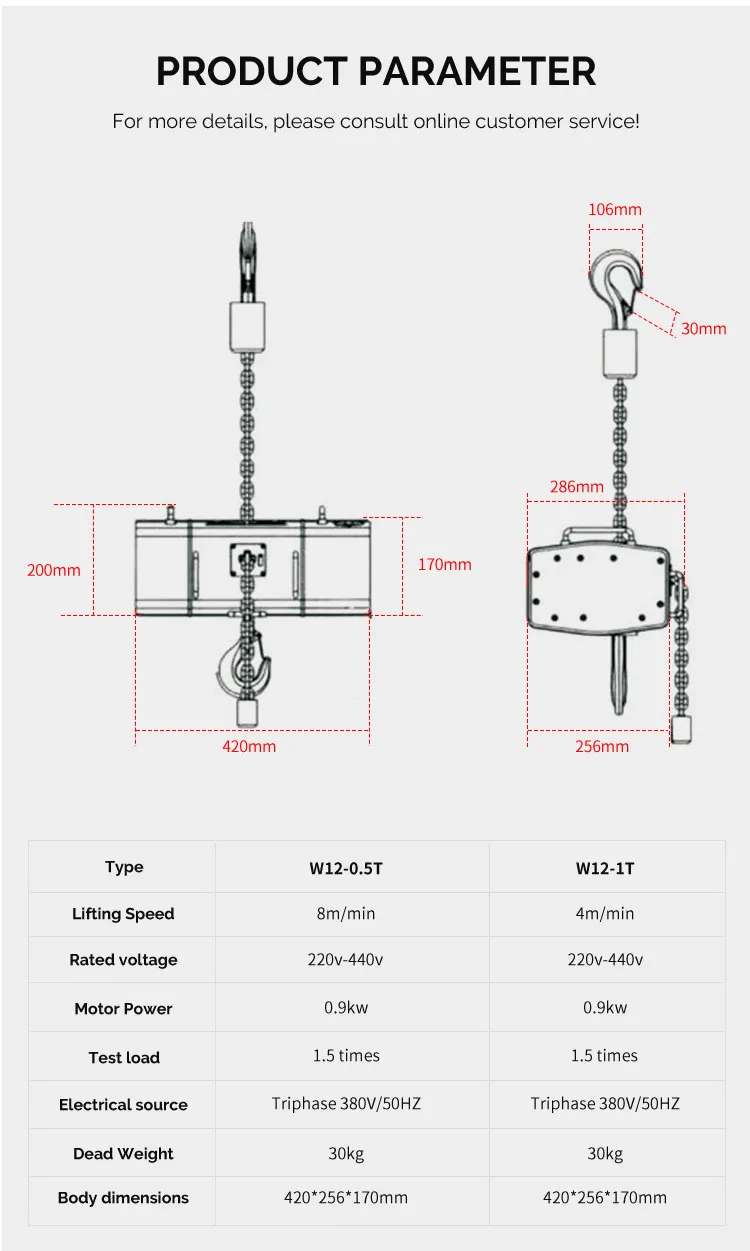

The W12 series products are electric hoists specially designed for stages, also known as self-climbing electric hoists. They can achieve two lifting methods: front suspension and inverted suspension.

Category : W12 Stage Electric Hoist

Get a Quote

Product Details

Product Name: W12 Stage Electric Hoist

Product Type: Stage Electric Hoist

Product Description:

Tianjin Kemei Machinery Manufacturing Co., Ltd. is a modern production - oriented enterprise integrating independent R & D, manufacturing, and sales. The company's main products include stage electric hoist, stage chain hoist, black lifting slings, group controller, rail clamps, and auxiliary products.

Product Specifications:

1.Dual - brake system ensures product safety and braking accuracy, minimizing errors during synchronous control.

2.With an IP56 protection rating, it features a waterproof design and has passed the tests of exposure to rain and immersion in water.

3.The product comes with upper and lower limit switches and is equipped with adjustable limit blocks.

4. The outer shell of the whole machine is made of aviation aluminum, making the body lighter.

Debugging and Maintenance of Upper and Lower Limit Switches Debugging:

After the installation process of the stage electric hoist is completed, it is particularly crucial to carry out precise debugging of the upper and lower limit switches according to the actual working conditions on site and the usage requirements. By finely adjusting the spatial position of the limit block, the running boundaries of the electric hoist in the vertical direction can be accurately defined, ensuring that it is strictly confined within the safe working range. The specific operation process is as follows: First, control the hoist to rise at a uniform speed to the preset upper limit position, and use professional tools to finely adjust the upper limit switch until the switch is triggered, achieving the precise stop of the hoist. Subsequently, lower the hoist smoothly to the lower limit position, and calibrate the lower limit switch in the same rigorous manner to ensure the accuracy of the lower limit position setting. Throughout the entire debugging process, it is necessary to strictly control the precision, conduct repeated verifications, and comprehensively consider parameters such as the load condition and running speed at the same time, so as to ensure the triggering sensitivity and reliability of the limit switches. Maintenance:

In order to ensure that the upper and lower limit switches of the W12 stage electric hoist are always in the best working condition, it is necessary to formulate and implement a periodic maintenance inspection plan. The maintenance content covers several key aspects. Firstly, check whether the fixed base of the limit switch is stable and whether there are signs of looseness or displacement, ensuring that it will not shift in position due to factors such as vibration and impact during the operation of the equipment. Secondly, carefully inspect the connecting wires to check for potential hazards such as outer skin damage, internal wire breakage, or looseness, ensuring the stability and reliability of the electrical connection. Thirdly, pay close attention to the wear condition of the limit block. If it is found that the wear degree exceeds the allowable tolerance range, replace it in a timely manner. Once any abnormalities are detected during the inspection process, immediately initiate the repair or replacement procedure. Use professional detection equipment and maintenance tools to repair or replace the faulty components, and make every effort to ensure that the limit switches always maintain reliable working performance, laying a solid foundation for the safe and stable operation of the stage electric hoist.

Application scenarios of stage electric hoists

If you need further consultation on stage electric hoist details, please contact Google email

Gmail : info@kemeihoist.com

zyj@kemeihoist.com

WhatsApp:+86 13920508123

RELATED PRODUCTS .

The flexible lifting sling is a kind of lifting tool used in lifting operations. It is usually made of high-strength fiber materials or metal ropes with a flexible outer layer. It has the characterist

The truss hoist controller, relying on its precise algorithm, can synchronously and accurately manipulate dozens of hoists to lift and lower in coordination. It makes the stage mechanical devices coop

The manual stage chain hoist is easy to operate. Even volunteers who are new to stage equipment can quickly get the hang of it and complete the lifting and lowering work of small props.

Advanced stage winches usually utilize electric motors or hydraulic systems to provide power, and achieve the lifting, lowering, and positioning of heavy objects through a series of mechanical transmi

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record