X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

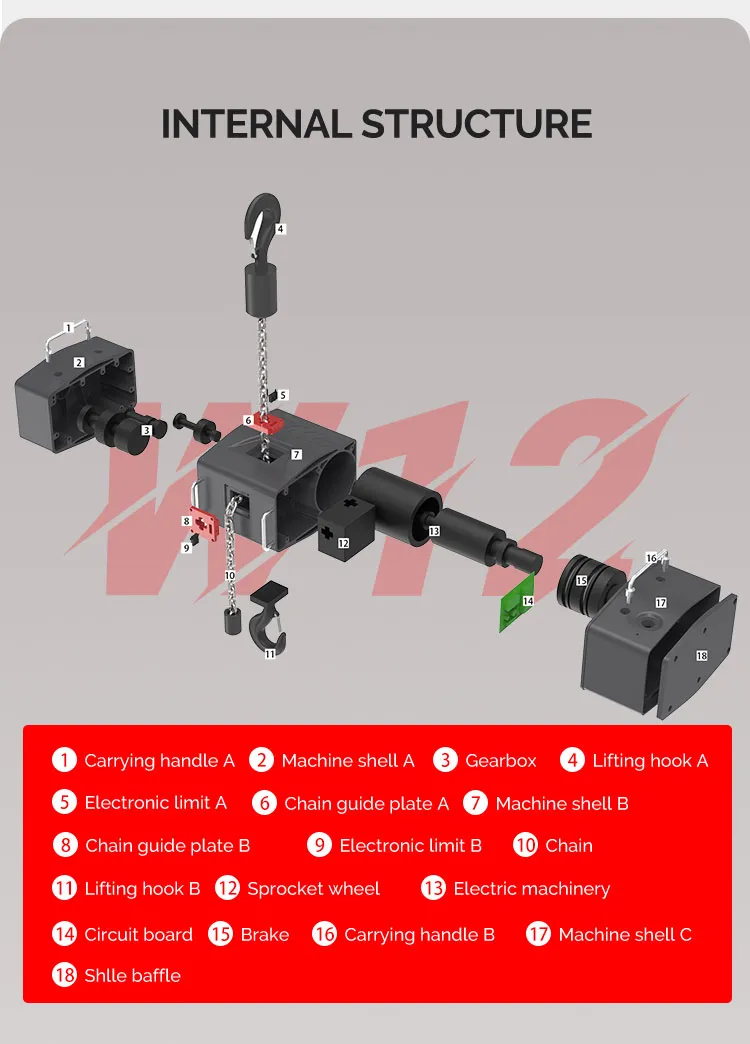

The W12 stage-specific electric hoist, also known as the self- hanging. It is mainly applicable to the construction of commercial stages, stage scenery, audio and lighting arrangements, as well as ban

Category : W12 Stage Electric Hoist

Get a Quote

Product Details

The accuracy of the positioning of the stage electric hoist can be inspected from the following aspects: Preparation Work - **Familiarize with Equipment Information**: Thoroughly understand the technical parameters, operation manuals, and relevant installation drawings of the electric hoist to clarify information such as its designed positioning accuracy indicators. - **Prepare Inspection Tools**: Tools such as laser rangefinders, steel tapes, and dial indicators should be prepared. Ensure that these tools are calibrated and their accuracy meets the inspection requirements. - **Ensure Safety**: Before inspection, be sure to cut off the power supply and set up obvious safety warning signs in the operation area to prevent accidents. At the same time, check whether the safety devices of the electric hoist, such as the braking device and limit switches, are working properly. Static Inspection - **Appearance Inspection**: Check whether the electric hoist is installed firmly and whether there are obvious deformations, damages, or looseness in each component. Pay special attention to transmission components such as chains and wire ropes. Conditions such as wear and strand breakage may affect the positioning accuracy. - **Limit Switch Inspection**: Manually trigger the upper and lower limit switches to check whether they can act accurately to stop the operation of the electric hoist. At the same time, check whether the installation positions of the limit switches are correct and whether they match the stroke range of the electric hoist. - **Brake Inspection**: Check whether the braking gap of the brake is appropriate and whether the brake pads are severely worn. You can observe whether the electric hoist slips in the stopped state by manually turning the handwheel. Dynamic Inspection - **No - load Running Test** - **Inching Operation**: Connect the power supply and perform inching up and down operations. Observe whether the operation of the electric hoist is stable, and check for any jamming, shaking, or abnormal noises. The stroke of each inching operation should be as small as possible, for example, 50mm or 100mm, to observe its positioning more accurately. - **Full - range Running**: Let the electric hoist run up and down the full range several times under no - load conditions. Record the actual positions when it reaches the upper and lower limit positions each time, and compare them with the theoretical positions. The deviation should be within the allowable range, generally not exceeding ±5mm. - **Load Running Test** - **Loading Test**: Select appropriate weights for loading according to the rated load of the electric hoist. Generally, 50%, 75%, and 100% of the rated load can be selected for testing respectively. After loading, repeat the inching and full - range running operations in the no - load running test. - **Observation and Recording**: During the load running process, focus on observing the state of the electric hoist during startup, operation, and stop to check for any obvious displacement deviations. Especially when it stops, record the deviation between its actual stop position and the set position. For stage electric hoists with high - precision requirements, the positioning deviation under load should generally be controlled within ±10mm. - **Accuracy Measurement** - **Use of Laser Rangefinder**: Fix the laser rangefinder in a stable position so that it can accurately measure the position changes of the hook or load of the electric hoist. During the operation of the electric hoist, use the laser rangefinder to measure the distance from it to the target position in real - time and record the data. - **Installation of Dial Indicator**: Install a dial indicator on the running track or relevant components of the electric hoist. Measure the displacement deviation of the electric hoist during operation through the pointer change of the dial indicator. The dial indicator has high accuracy and can detect small displacement changes, which can be used for accurate measurement of positioning accuracy. Data Recording and Analysis - **Record Data**: Record the results of each test in detail, including the actual positioning positions and deviation values under no - load and load conditions, and form an inspection report.

- **Data Analysis**: Analyze the recorded data to observe whether the positioning deviation has regularity, such as whether it is always deviated in a certain direction, or whether the deviation value increases with the increase of the load. If the positioning deviation is found to exceed the allowable range, promptly find the cause, such as checking whether the motor speed is stable, whether the transmission components are worn, or whether the control system has a fault, and make corresponding adjustments and repairs.

RELATED PRODUCTS .

The polyester black lifting sling also features non-conductivity and no corrosion, ensuring safety and wide applicability. These characteristics make it an efficient and reliable hoisting tool, especi

The aircraft case truss hoist controller is suitable for the quick installation and adjustment of stage lighting, sound systems, and other equipment. It performs exceptionally well in enviro

Factory-direct hand-pulled stage hoists are ideal for the quick installation and adjustment of stage lighting, sound systems, and other equipment. They perform exceptionally well in environments witho

The stage truss motor equipped with a limit switch deeply integrates powerful performance, precise control, and excellent safety. It can not only easily handle the hoisting and accurate positioning of

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record