X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

Inspection and usage precautions for group hoist

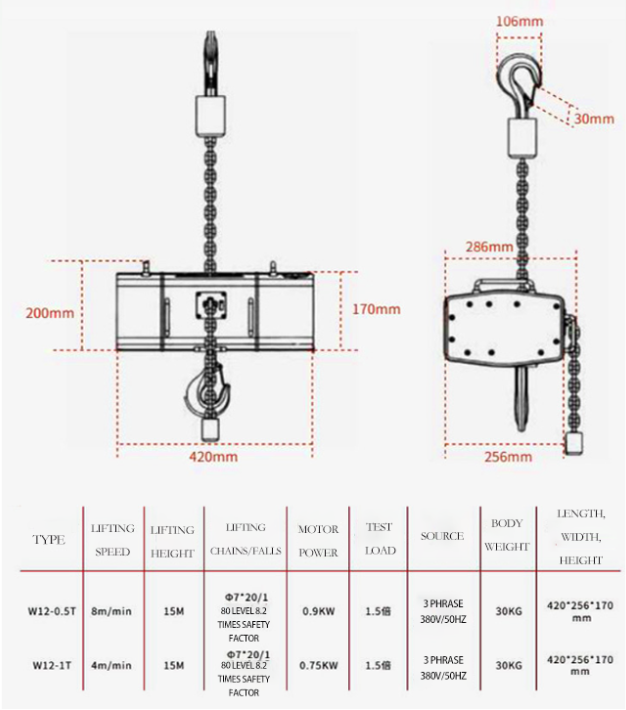

Category : W12 Stage Electric Hoist

Get a Quote

Product Details

Inspection and usage precautions for group hoist

1、 Pre use inspection of group crane electric hoist:

① There should be no obstacles within the walking range of the operator and on the route through which heavy objects pass.

② The manual buttons should move accurately and sensitively in the up and down, left and right directions, and the motor and reducer should have no abnormal sound.

③ The brake should be sensitive and reliable.

④ There should be no foreign objects on the running track of the group crane electric hoist.

⑤ The action of the upper and lower limit switches should be accurate.

⑥ The locking nut of the hook should be tightened.

⑦ The hook should rotate flexibly in both horizontal and vertical directions.

⑧ The hook pulley should rotate flexibly.

2、 During the use of the group crane electric hoist, if any faults are found, the main power supply should be cut off in a timely manner.

3、 During use, operators should always check the steel wire rope for any loose buckles, knots, grooves, wear, etc. If any problems occur, they should be promptly eliminated, and the rope guide and limit switch should be regularly checked for safety and reliability.

4、 In daily work, it is not allowed to artificially use limiters to stop lifting heavy objects or stopping equipment operation.

5、 It is prohibited to press two buttons in opposite directions at the same time, while others can be operated simultaneously.

6、 Special maintenance personnel should be assigned to inspect the main performance and safety status of the electric hoist once a week, and promptly eliminate any faults found.

7、 The brake ring on the brake wheel of the electric motor fan should not be contaminated with oil stains, and the adjusting nut should be tightened to avoid accidents caused by brake failure.

8、 The lubrication parts of the group crane electric hoist should be promptly lubricated with an appropriate amount of lubricating oil, which should be clean and free of other impurities. Lubricating oil should be replaced approximately every 2 months. Sufficient lubricating oil must be added to the lifting reducer and operating reducer before use.

9、 Group hanging electric hoists are not suitable for places filled with corrosive gases or with relative humidity greater than 85%. They cannot replace explosion-proof hoists and are not suitable for lifting molten metals or toxic, flammable, and explosive materials.

10、 When the group crane electric hoist is not working, it is not allowed to hang heavy objects in the air to prevent permanent deformation of components.

11、 After use, it should be parked in a designated safe place. Rainproof covers should be installed outdoors.

12、 The electric hoist for group hoisting shall not be used to lift or unload heavy objects on the side, and overloading is prohibited.

13、 When disassembling the lifting reducer for maintenance, do not use screwdrivers, flat shovels, etc. to hit the joint surface. Use a wooden hammer to gently tap the protruding part of the box to avoid damaging the sealing plane between the box and the box cover.

14、 The working environment temperature of the electric hoist is -25~+40 ℃. After working, turn off the main power switch and cut off the main power supply

RELATED PRODUCTS .

Wholesale lifting slings often come with a more professional technical team and after-sales service. They can provide customers with professional advice and training on the selection, use, and mainten

The motor controller for celebrity concerts precisely regulates the lifting of the stage elevators, ensuring that the stars make a stunning appearance during the grand opening ceremony and achieving a

The hand chain winch specially designed for theater performances acts as the "emergency guardian" of stage shows, relying on its stable and reliable pure manual control system. In emergency ...

In large-scale concerts, electric stage hoists can enable flexible transformations of the stage's mechanical structure, such as lifting and lowering the main stage and moving the extended stage, creat

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record