X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

With the rapid development of the economy and the construction of cities, the development of the lifting industry is becoming increasingly fast, and the use of lifting chains is also becoming more and

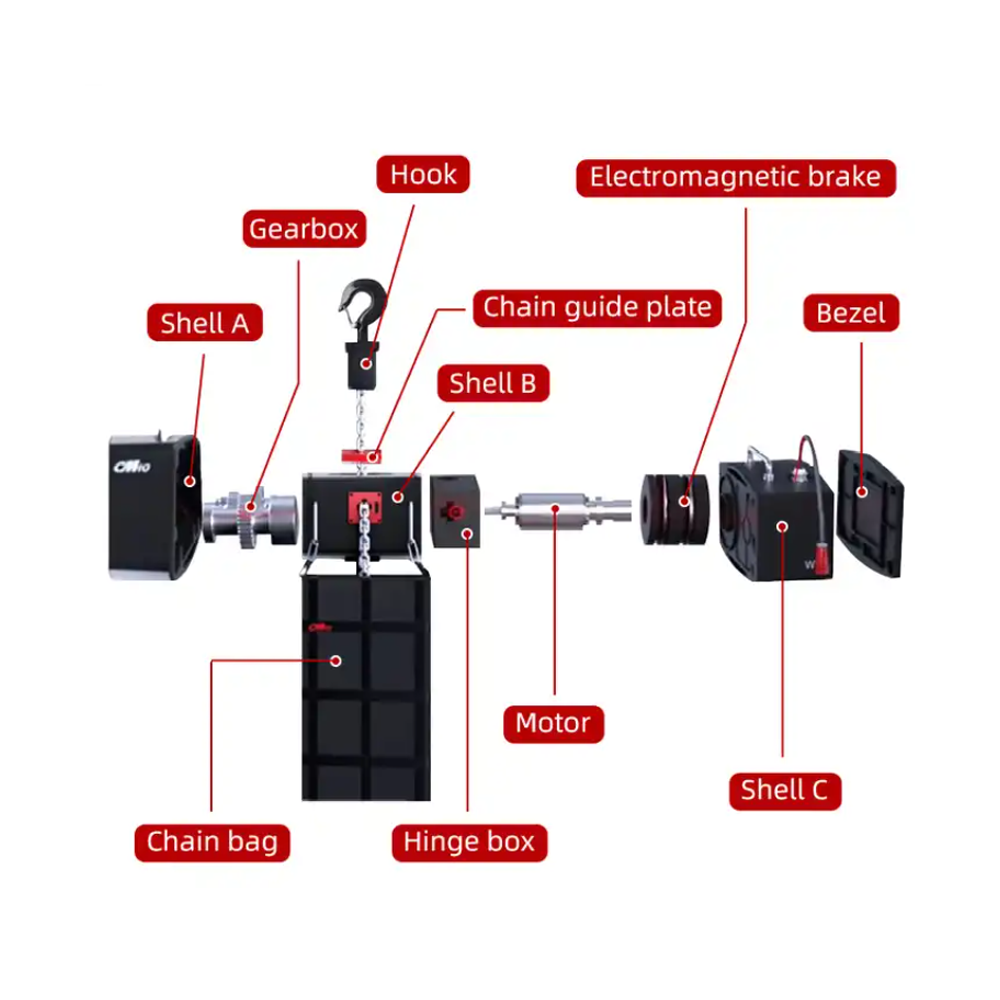

Category : W12 Stage Electric Hoist

Get a Quote

Product Details

Discussion on the causes and hazards of crane chain breakage

With the rapid development of the economy and the construction of cities, the development of the lifting industry is becoming increasingly fast, and the use of lifting chains is also becoming more and more widespread. No matter under what circumstances it is used, safety is of utmost importance. Below, the editor will explain to you the reasons that affect the breakage of lifting chains and the accompanying hazards.

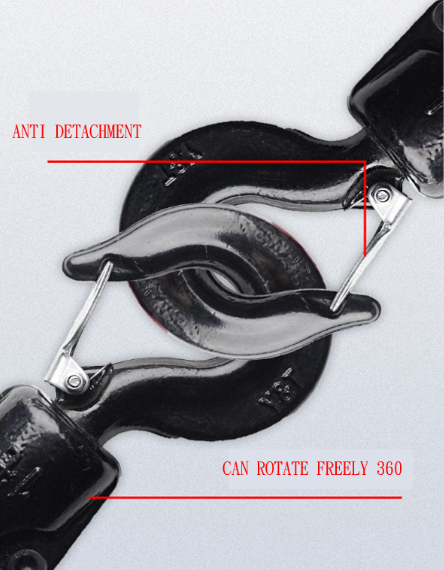

Firstly, rust is a contributing factor to chain breakage. Rust can change the chemical structure of the chain, causing the texture of the chain to become loose, resulting in a decrease in the overall strength and toughness of the chain. The possibility of chain fracture during the process will be greatly increased, and the fracture surface is generally the rusted part.

Secondly, overloading and long-term fatigue use are another contributing factor to chain breakage. Each type of lifting chain has its own rated load, and overloading can easily cause deformation or breakage of the chain.

Once the lifting chain breaks, it is easy to cause harm to goods and personnel, especially during high-altitude lifting. Therefore, it is strictly prohibited for personnel to stand below during lifting to avoid injury. The lifting chain produced has a safety factor of 4 times, and generally does not break without overloading or severe rust.

Crane chains are often used in environments with high load-bearing capacity. During use, excessive wear and tear can have varying degrees of impact on operational safety. To reduce the degree of wear and tear, only two methods are needed:

1. During use and maintenance, apply a thin layer of lubricating oil evenly on its surface, and let it stand for a period of time. After the grease is fully absorbed, use it again to reduce wear.

2. Choose a suitable chain for operation according to actual needs. If any abnormal operation occurs during use, please stop the operation in a timely manner and inspect the lifting chain. This can also achieve the goal of reducing wear and tear.

RELATED PRODUCTS .

Wholesale lifting slings often come with a more professional technical team and after-sales service. They can provide customers with professional advice and training on the selection, use, and mainten

The motor controller for celebrity concerts precisely regulates the lifting of the stage elevators, ensuring that the stars make a stunning appearance during the grand opening ceremony and achieving a

The hand chain winch specially designed for theater performances acts as the "emergency guardian" of stage shows, relying on its stable and reliable pure manual control system. In emergency ...

In large-scale concerts, electric stage hoists can enable flexible transformations of the stage's mechanical structure, such as lifting and lowering the main stage and moving the extended stage, creat

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record