X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

Stage electric hoists are valuable aids in building stage scenes and presenting performances. They play a crucial role in various settings, such as theaters, concerts, opera houses, dance venues, and

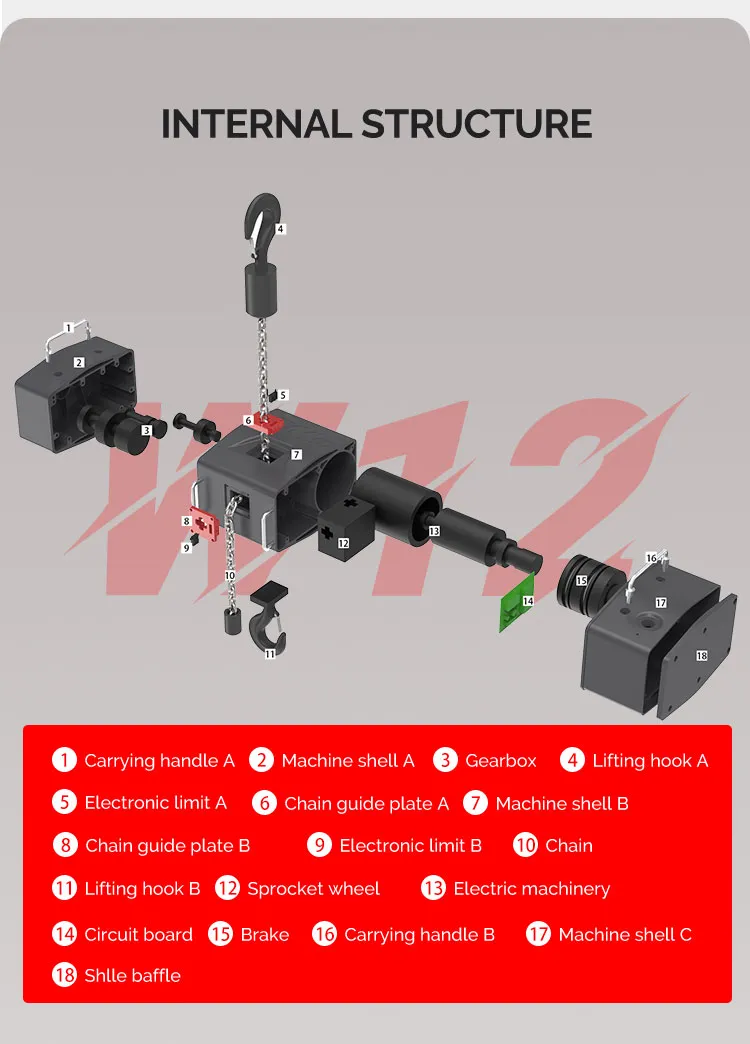

Category : W12 Stage Electric Hoist

Get a Quote

Product Details

- **Inspection of Other Safety Devices**: Check whether other safety devices of the electric hoist, such as the chain - breakage protection device and derailment - prevention device, are working properly. These safety devices should play a corresponding protective role in case of unexpected situations to ensure the safety of the electric hoist and operators.

RELATED PRODUCTS .

stage lifting slings are brightly colored, making it easy for workers to quickly identify and operate them on the stage. They also feature excellent abrasion resistance and chemical corrosion resistan

The stage electric hoist controller —tap your finger and witness the extraordinary. With precise signal transmission, outstanding adaptability and compatibility, it meets every stage requirement seaml

The Stage Hand Winch is a specialized lifting device designed for precise load handling in theaters, performance venues, and event spaces. Its compact size belies its powerful capabilities, making it

The stage electric hoist is a capable assistant on the entertainment stage. It has the ability to lift and lower rapidly, meeting the needs of frequent stage scene changes. It can quickly position equ

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record