X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

In stage equipment, the stage electric hoist plays a crucial role as it can safely and efficiently lift and move various stage props and equipment. In order to ensure the reliability and safety of t

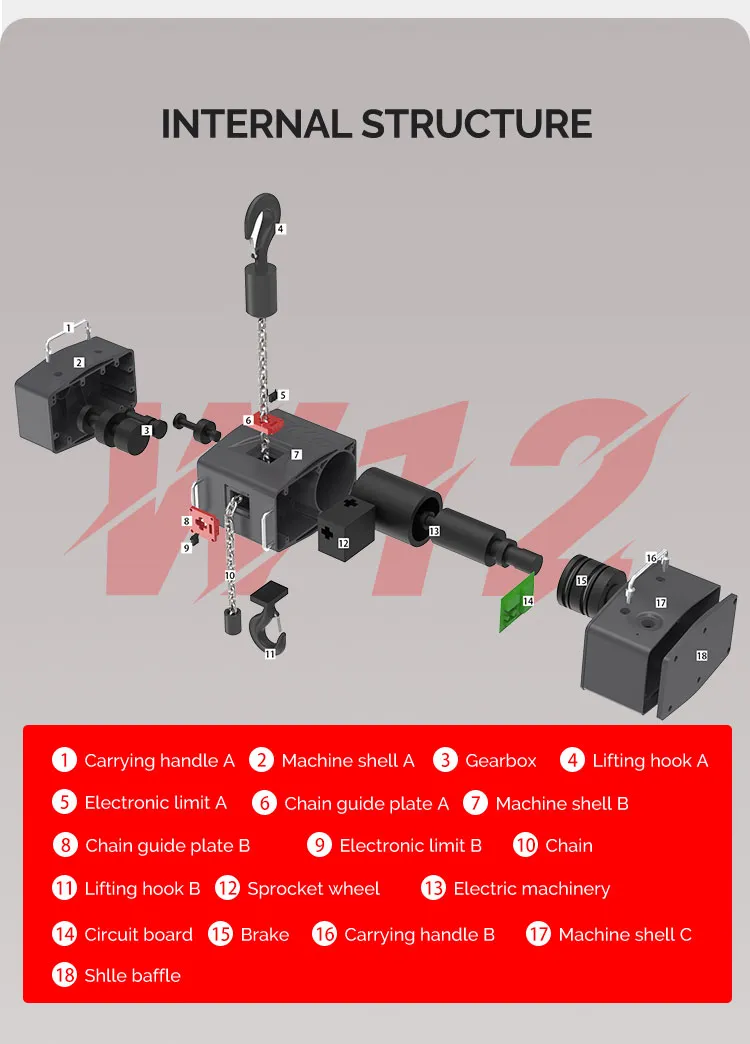

Category : W12 Stage Electric Hoist

Get a Quote

Product Details

Detailed explanation of the trial pulling process of stage electric hoist

1、 Preparation work before trial pulling

(1) Check the appearance of the electric hoist

Check whether the outer shell of the electric hoist is damaged, deformed, or not.

Check for cracks, deformations, and other defects in components such as hooks and chains.

Confirm whether the electrical circuit of the electric hoist is connected correctly and undamaged.

(2) Choose a trial site

The trial site should be flat, solid, and free of obstacles.

The space of the venue should be large enough to ensure that the electric hoist has sufficient activity space during the trial pulling process.

(3) Prepare to try pulling heavy objects

Select a suitable trial load based on the rated load of the electric hoist.

The weight of the test load should gradually increase to simulate different load situations in actual use.

2、 Trial pull process steps

(1) No load trial operation

Hang the electric hoist on a suitable bracket without connecting it to a test load.

Connect the power supply, start the electric hoist, and conduct a no-load test run.

Observe the operation of the electric hoist, including whether the ascending and descending speeds are stable, and whether there are any abnormal noises and vibrations.

Check if the control buttons of the electric hoist are sensitive and reliable, and if the limit switch is working properly.

(2) Light load test pull

After the no-load test run is normal, connect a lighter test load, usually 20% to 30% of the rated load.

Start the electric hoist, slowly lift the trial load to a certain height, and then slowly lower it.

Observe the operation of the electric hoist under light load, check whether the tension of the chain is appropriate, and whether there is abnormal wear on the transmission components.

(3) Mid load test pull

Gradually increase the weight of the test load to reach 50% to 70% of the rated load.

Repeat the lifting and lowering operations and observe the performance of the electric hoist under medium load conditions.

Check the heating condition of the motor and whether the braking effect of the brake is good.

(4) Full load test pull

Connect a test load equal to the rated load of the electric hoist.

Perform full load lifting and lowering operations, run continuously for a period of time, to simulate long-term working conditions in actual use.

Pay close attention to the various performance indicators of the electric hoist, such as lifting speed, lowering speed, motor current, etc., to ensure that they are within the normal range.

Check the structure of the electric hoist for any deformation, looseness, or other issues.

(5) Overload test pull (optional)

In special circumstances, an overload test can be conducted, but the overload amount should generally not exceed 110% of the rated load.

The purpose of overloading test is to verify the safety performance of electric hoists in emergency situations.

Overloading test should be conducted under the supervision of professional personnel, and the time should not be too long. Once any abnormal situation is found, the test should be stopped immediately.

3、 Inspection and summary after trial pulling

(1) Check all components of the electric hoist

After the trial pulling is completed, check again whether the shell, hook, chain, motor, brake and other components of the electric hoist are damaged or abnormal.

Check the electrical circuit for overheating, short circuits, and other phenomena.

(2) Summarize the results of the trial pull

Evaluate the performance of the electric hoist based on observations and records during the trial pulling process.

If any problems are found, they should be repaired or adjusted in a timely manner to ensure that the electric hoist is in good condition before formal use.

Summarize the experience of trial pulling to provide reference for future product improvement and quality control.

RELATED PRODUCTS .

The stage electric hoist sling is an integrated lifting system specially designed for the hoisting of stage equipment. It is usually composed of an electric hoist and supporting slings (such as steel

The intelligent stage motor control cabinet is used in scenarios such as theaters and concerts. It coordinates multiple motors (such as elevators, turntables, and lighting racks) through intelligent a

Relying on its reliability, economy, and environmental adaptability, the manual chain hoist continues to play an important role in both industrial and civil fields. When making a selection, it is nece

The constant-speed truss hoist is used to lift and lower the stage background curtain, providing different scene transitions for the performance. The constant-speed hoist enables the curtain to move u

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record