X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

Application scenarios of stage electric hoists include the construction of stage trusses, as well as the installation of audio and lighting equipment.

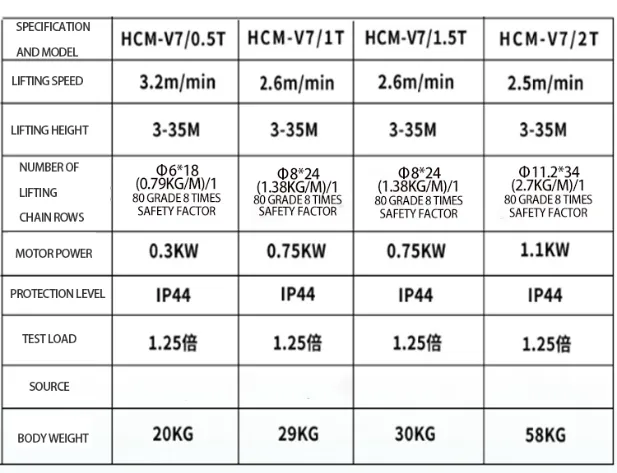

Category : V7 Stage Electric Series

Get a Quote

Product Details

To select a suitable stage electric hoist, multiple factors such as load capacity, lifting height, operating speed, safety performance, brand and after - sales service need to be comprehensively considered. The following are the specific key points: 1. Load Capacity - Clarify actual needs: The selection should be based on the weight of the objects to be lifted. For example, when building a large - scale stage truss, the weight of the truss itself and the possible weight of other equipment to be mounted, such as lights and audio systems, need to be taken into account. Generally, small - sized stage lighting equipment may weigh several dozen kilograms, while large - scale trusses and their attached equipment may weigh several tons. It is necessary to ensure that the rated load of the electric hoist is greater than the actual load. - Reserve a safety margin: To ensure safety and the service life of the equipment, it is usually recommended to choose an electric hoist whose rated load is 20% - 30% higher than the actual maximum load. 2. Lifting Height - Measure the installation space: The height of the stage and the distance between the installation position of the electric hoist and the highest point to be lifted are crucial. For example, the height of some large - scale theater stages may reach more than 10 meters, while small - sized indoor stages may only be 3 - 5 meters. An electric hoist that can meet the requirements should be selected according to the actual height. - Consider special requirements: If there are special performance needs, such as actors descending from a relatively high position, an additional margin for the lifting height should be considered. 3. Operating Speed - Performance rhythm requirements: For fast - paced performances, such as hip - hop performances and fast - paced musicals, lights, props, etc. may need to change positions quickly. Therefore, the electric hoist needs to have a relatively fast operating speed. Generally, an operating speed between 0.1 - 2 meters per minute can meet most requirements. - Operation accuracy requirements: If high - precision positioning of lights and props is required, such as in some performances that need precise follow - spot lighting, an electric hoist with a slower speed and precise control may be needed to reach the designated position more accurately. 4. Safety Performance - Brake system: A reliable brake system is crucial, such as electromagnetic brakes and mechanical brakes. An electric hoist with dual - brake or multiple - brake functions should be selected to ensure that it can stop immediately in case of power failure or malfunction. - Safety protection devices: Functions such as overload protection and limit protection are necessary. Overload protection can prevent the electric hoist from being damaged or in danger due to overloading, and limit protection can avoid lifting or lowering beyond the set range. 5. Control Methods - Manual control: For some small - sized stages or simple operation scenarios, a manually - controlled electric hoist may be sufficient. It can be operated up and down through a push - button box, which has a lower cost and is easy to operate. - Remote control: In large - scale stages or scenarios that require flexible operation, remote control is more convenient. Operators can operate from different positions on the stage, improving the flexibility and convenience of operation. - Intelligent control system: For some high - end stages, it may be necessary to integrate with the overall stage control system to achieve automated control, such as automatically controlling the lifting of lights and props according to the performance process. 6. Installation Methods - Fixed installation: If the installation position of the electric hoist is fixed and does not need to be moved frequently, fixed installation is more appropriate. It can be fixed to the structure above the stage through bolts, etc. - Mobile installation: For situations where it needs to be used in different positions, such as in some touring performances or multi - functional stages, a mobile electric hoist can be selected, which is convenient for installation and use in different positions. 7. Brand and After - sales Service - Brand reputation: Choosing electric hoists from well - known brands usually ensures better product quality, performance, and reliability. International brands such as Yale and Demag, as well as domestic brands such as Weihua and Yufei, have a good reputation in the industry. - After - sales service: Good after - sales service is of great importance, including product maintenance, repair, and spare parts supply. A supplier that can provide timely and professional after - sales service should be selected so that the equipment can be restored to use as soon as possible in case of failure. 8. Budget Cost - Comprehensive evaluation: On the premise of meeting the stage requirements, select a suitable electric hoist according to the project budget. Do not blindly pursue high - end products, nor choose products with unreliable quality to save costs.

- Long - term cost: In addition to the purchase cost, the operating cost and maintenance cost of the equipment also need to be considered. For example, although some high - quality electric hoists have a relatively high purchase price, they have a long service life and low maintenance cost, which may be more cost - effective in the long run.

RELATED PRODUCTS .

The polyester black lifting sling also features non-conductivity and no corrosion, ensuring safety and wide applicability. These characteristics make it an efficient and reliable hoisting tool, especi

The aircraft case truss hoist controller is suitable for the quick installation and adjustment of stage lighting, sound systems, and other equipment. It performs exceptionally well in enviro

Factory-direct hand-pulled stage hoists are ideal for the quick installation and adjustment of stage lighting, sound systems, and other equipment. They perform exceptionally well in environments witho

The stage truss motor equipped with a limit switch deeply integrates powerful performance, precise control, and excellent safety. It can not only easily handle the hoisting and accurate positioning of

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record