X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

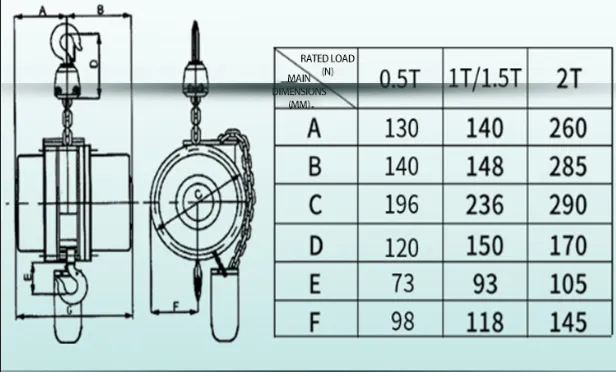

The electric hoist specially designed for stage trusses is truly a "capable assistant" on the stage. It is compact in shape yet has a strong lifting capacity, easily handling the lifting and lowering

Category : V7 Stage Electric Series

Get a Quote

Product Details

The maintenance steps of stage electric hoists usually include pre - maintenance preparation, fault diagnosis, specific repair, and post - repair testing. The following is a detailed introduction: Pre - maintenance Preparation 1. **Preparation of Safety Protective Equipment**: Maintenance personnel need to wear necessary safety protective equipment such as safety helmets, safety shoes, and gloves to ensure their own safety. 2. **Preparation of Tools and Equipment**: Prepare the required maintenance tools, such as wrenches, screwdrivers, vernier calipers, multimeters, etc., as well as possible professional testing equipment, such as insulation resistance testers. 3. **Data Review**: Review relevant technical data, operation manuals, and maintenance records of the electric hoist to understand information such as the equipment's specification parameters, working principle, common faults, and repair methods. 4. **On - site Safety Inspection**: Check whether the maintenance site has good ventilation and lighting conditions, and whether there are obstacles or other risk factors around to ensure the safety of the maintenance work environment. ### Fault Diagnosis 1. **Inquire with Users**: Ask the operators of the electric hoist about the specific situation of the fault, including the time of occurrence, symptoms, whether there are abnormal sounds or odors, and whether there are special circumstances during the operation. 2. **Appearance Inspection**: Conduct a comprehensive appearance inspection of the electric hoist to check for obvious damage, deformation, wear, cracks, etc., especially in parts such as the hook, chain, wire rope, and housing. 3. **Electrical System Inspection** - Use a multimeter to check whether the power supply voltage is normal, whether the connections of various electrical components are firm, and whether there are any loose or ablated phenomena. - Check whether the wires and cables have problems such as damage, aging, and leakage, and use an insulation resistance tester to measure whether the insulation resistance meets the requirements. - Check whether the components of the control circuit, such as switches, contactors, and relays, are working normally and whether their actions are sensitive and reliable. 4. **Mechanical System Inspection** - Manually rotate components such as the driving wheel and sprocket of the electric hoist to check whether they rotate flexibly and whether there are any jams, abnormal noises, etc. - Check whether the tension of the chain is appropriate, whether the meshing between the chain and the sprocket is good, and whether there are problems such as tooth skipping and chain derailment. - Check the wear and broken wire conditions of the wire rope, and whether the fixed end of the wire rope is secure. - Check whether the braking clearance of the braking device meets the requirements and whether the braking is sensitive and reliable. ### Specific Repair 1. **Repair or Replacement of Mechanical Components** - **Hook Repair**: If the hook has slight wear or deformation, it can be repaired and polished; if the wear or deformation is severe, or there are defects such as cracks, a new hook must be replaced. - **Chain Repair**: If the chain has elongation, deformation, or loose pins, it can be adjusted or replaced; if the chain is severely rusted, rust removal treatment should be carried out or the chain should be replaced. - **Wire Rope Replacement**: When the wire rope has serious broken wires, wear, rust, or distortion, a new wire rope needs to be replaced according to the specified method, and ensure that the installation and fixation of the wire rope are correct. - **Bearing and Gear Repair**: Check the wear conditions of the bearings and gears. If there are problems such as severe wear and damage, the bearings and gears should be replaced in a timely manner. During the installation process, pay attention to ensuring the installation accuracy and fit clearance. - **Braking Device Repair**: Adjust the braking clearance of the braking device to meet the requirements; if the brake pads are severely worn, replace the brake pads; check whether components such as the braking spring have good elasticity, and replace them in a timely manner if there are problems. 2. **Repair or Replacement of Electrical Components** - **Power Cord Repair**: Replace damaged and aged power cords; if the plug and socket have poor contact, they can be repaired or replaced. - **Replacement of Electrical Components**: Replace ablated and damaged electrical components such as contactors, relays, and limit switches according to the original model, and ensure correct wiring. - **Control System Repair**: Check whether there are faults in the circuit boards and electronic components of the control circuit. If there are problems, the circuit boards can be repaired or replaced. For some complex electrical faults, professional testing equipment and technical means may be required for troubleshooting and repair. Post - repair Testing 1. **No - load Running Test**: Without loading heavy objects, connect the power supply and let the electric hoist run up and down to check whether its operation is stable, whether there are abnormal sounds, vibrations, etc., and whether each control button and limit switch are working normally. 2. **Load Test**: Select an appropriate heavy object for the load test according to the rated load of the electric hoist. First, conduct a step - by - step loading test at 50%, 75%, and 100% of the rated load to check the operation of the electric hoist under different loads, including whether functions such as lifting, lowering, and braking are normal, and whether there are problems such as overheating, deformation, and abnormal noises in each component. 3. **Braking Test**: During the load test, conduct braking tests at different heights to check whether the braking distance of the braking device meets the requirements and whether the braking is reliable, ensuring that it can brake quickly in case of an emergency to prevent heavy objects from falling. 4. **Limit Test**: Manually operate the electric hoist to reach the upper and lower limit positions, and check whether the limit switch can act accurately, cut off the power supply in a timely manner, and stop the operation of the electric hoist to ensure the reliability of the limit function.

After the maintenance is completed, record in detail the information such as the replaced parts, maintenance time, maintenance personnel, and post - repair test results during the maintenance process, and update the maintenance file.

Previous: Electric Chain Hoist For Stage

RELATED PRODUCTS .

The lifting sling is a flexible rigging used for lifting operations. It is usually made of high-strength fiber materials such as polyester fibers and aramid fibers, and some are also composed of metal

The stage hoist controller is a device used to control the hoist devices on the stage (usually electric hoists or hand chain hoists and other lifting equipment). It is mainly used to precisely adjust

The lifting capacity of the light hand chain hoist for the stage is also related to factors such as the usage environment, operation mode, and the setting of the safety factor. In practical use, it is

The electric hoist for truss is an electric hoisting device specially designed for hoisting and moving truss structures. It has precise positioning and control functions, enabling it to accurately hoi

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record