X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

Stage electric hoists are valuable aids in building stage scenes and presenting performances. They play a crucial role in various settings, such as theaters, concerts, opera houses, dance venues, and

Category : V7 Stage Electric Series

Get a Quote

Product Details

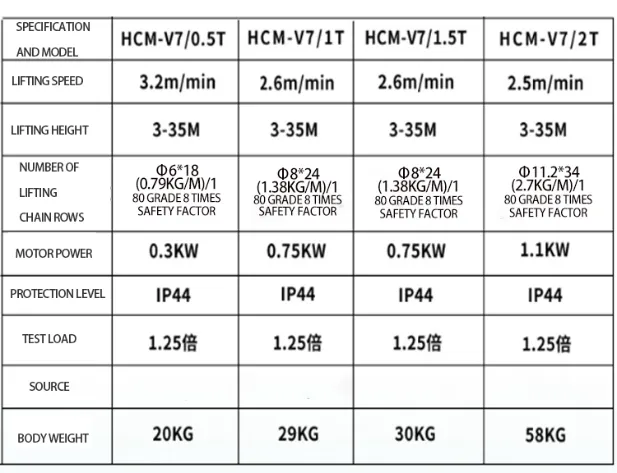

Product Name: V7 Stage Electric Hoist

Product Type: Stage Electric Hoist

Product Description: Tianjin Kemei Machinery Manufacturing Co., Ltd. is a modern production - oriented enterprise integrating independent R & D, manufacturing, and sales. It is located in the beautiful coastal city of Tianjin, enjoying a unique geographical location, convenient transportation, and smooth logistics. The company is committed to the development and manufacturing of stage entertainment lifting products. Its main products include stage - specific endless chain electric hoists, stage - specific hand chain hoists, black lifting slings, group control boxes, rail grippers, and auxiliary products. These products are widely used in the fields of truss construction for concerts, conference halls, exhibition hall fine decoration, high - end customized weddings, and various celebration performances. Product Specifications: 1. It adopts international G80 - grade lifting chains, featuring good safety performance and corrosion resistance. 2. The protection level reaches IP44, with a waterproof design, and has passed the tests of rain and water immersion. 3. It is equipped with a mechanical overload protection device and an anti - oil leakage setting. 4. The whole machine shell is made of aviation aluminum, making the body more lightweight. To ensure the safety of stage electric hoists, it can start from aspects such as equipment selection and installation, personnel operation and management, daily maintenance and inspection. The details are as follows: Equipment Selection and Installation Choose Qualified Products: Give priority to stage electric hoists from well - known brands with a good reputation and that meet relevant safety standards, such as the W12 stage electric hoist of Tianjin Kemei Machinery Manufacturing Co., Ltd., which has safety configurations like a double - brake system and an IP56 protection level. Correct Installation and Debugging Track Installation: The installation of the track should be carried out strictly in accordance with the design requirements and installation specifications to ensure the flatness and straightness of the track. The track should be firmly fixed to prevent deformation or loosening during use. Electrical Connection: Professional electricians should conduct the connection and wiring of the electrical system to ensure correct and firm wiring and good grounding, preventing electrical failures such as electric leakage and short - circuits. Debugging and Testing: After installation, comprehensive debugging and testing should be carried out, including no - load operation, load test, braking test, limit switch test, etc., to ensure that all performance indicators of the electric hoist meet the requirements and all safety devices work properly. Personnel Operation and Management Professional Training and Certification: Operators must undergo professional training, be familiar with the structure, performance, operation methods, and safety precautions of the stage electric hoist. Only after passing the assessment and obtaining the corresponding operation certificate can they start operating. Strictly Comply with Operating Procedures Pre - operation Inspection: Before each operation, operators should conduct appearance inspections, electrical system inspections, braking system inspections, etc. of the electric hoist, and start the operation only after confirming that there are no abnormalities. Standardize the Operation Process: Start and stop the operation smoothly, avoiding sudden starts and stops. During the lifting and lowering process, keep the lifted items stable and do not tilt or shake them. Multi - person Operation Coordination: When multiple people cooperate in the operation, the commander and command signals should be clearly defined. Operators should strictly follow the commands and not operate without permission. Safety Awareness Education: Regularly conduct safety awareness education for operators and relevant staff to improve their understanding of the importance of the safety of stage electric hoists, so that they can consciously abide by safety regulations and not operate in violation of the rules. Daily Maintenance and Inspection Establish a Maintenance System: Develop a detailed daily maintenance and regular inspection system, clarify the content, cycle, responsible person, etc. of maintenance and inspection to ensure the implementation of maintenance and inspection work. Component Inspection and Replacement Vulnerable Components: Regularly check the wear of vulnerable components such as chains, hooks, brake pads, and limit switches. If the wear exceeds the specified range or a component is damaged, replace it in a timely manner. Other Components: Check the working conditions of components such as motors, reducers, and brakes. If there are abnormal noises, vibrations, overheating, etc., repair or replace them in a timely manner. Record and File Management: Keep detailed records of each maintenance and inspection, including inspection time, content, problems found, handling results, etc. Establish an equipment maintenance file for easy access and analysis of the equipment's operating status at any time. Safety Management and Supervision Formulate an Emergency Plan: Develop a complete emergency plan, including response measures for various emergencies such as electric hoist failures, falling objects, and personnel injuries. Regularly organize drills to ensure that relevant personnel are familiar with the procedures and operation methods of the emergency plan. Safety Supervision and Inspection: Arrange special personnel or establish a safety supervision team to regularly supervise and inspect the use, maintenance, and operation of stage electric hoists, promptly discover and correct existing safety problems, and seriously deal with illegal operations and unsafe behaviors.

Regular Safety Assessment: Regularly invite professional institutions or experts to assess the safety of stage electric hoists. According to the assessment results, carry out necessary upgrades, renovations, or maintenance of the equipment to ensure that the equipment is always in a safe and reliable operating state.

RELATED PRODUCTS .

The lifting sling is a flexible rigging used for lifting operations. It is usually made of high-strength fiber materials such as polyester fibers and aramid fibers, and some are also composed of metal

The stage hoist controller is a device used to control the hoist devices on the stage (usually electric hoists or hand chain hoists and other lifting equipment). It is mainly used to precisely adjust

The lifting capacity of the light hand chain hoist for the stage is also related to factors such as the usage environment, operation mode, and the setting of the safety factor. In practical use, it is

The electric hoist for truss is an electric hoisting device specially designed for hoisting and moving truss structures. It has precise positioning and control functions, enabling it to accurately hoi

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record