X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

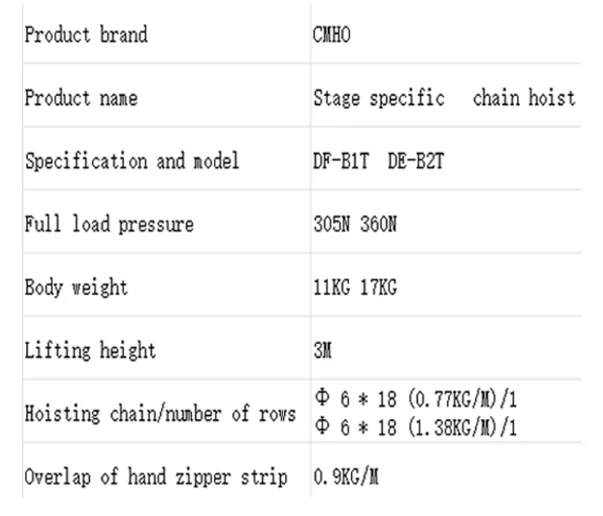

The stage hand - chain hoist is a capable little assistant on the stage. It has an exquisite structure, is effortless to install, occupies minimal space, and can be perfectly integrated into various s

Category : Stage Chain Hoist Series

Get a Quote

Product Details

The factory - exit inspection of stage hand - operated chain hoists covers multiple key aspects to ensure product quality and safe use. The main inspection contents are as follows: Appearance Inspection - Surface Quality: Check whether the surface of the hand - operated chain hoist is smooth and free from obvious casting defects such as blowholes, pores, and cracks. These defects may affect the strength and aesthetics of the product. - Coating Quality: Examine whether the coating is uniform and firm, and check for phenomena such as peeling, flaking, and rusting. A good coating can prevent the components of the chain hoist from rusting and corroding, thus extending its service life. - Component Integrity: Confirm whether all components, including chains, hooks, sprockets, brakes, etc., are complete. Check for any damaged or missing components to ensure that the product can be assembled and used normally. Dimensional Accuracy Detection - Measurement of Key Dimensions: Measure the key dimensions of the chain hoist, such as the pitch of the chain, the diameter of the sprocket, the opening of the hook, etc., to ensure that these dimensions meet the design requirements and relevant standards. This ensures the fitting accuracy between components and the overall performance of the chain hoist. - Tolerance Control: Check whether the dimensional tolerances are within the allowable range. Excessive tolerances may lead to poor fitting between components, affecting the operating flexibility and stability of the hand - operated chain hoist. Performance Testing - Lifting Capacity Test: Under the rated load, perform lifting and lowering operations on the hand - operated chain hoist. Check whether it can smoothly lift and lower heavy objects, and look for any abnormal phenomena such as jamming and slipping. Verify whether it has the lifting capacity required by the design. - Braking Performance Test: During the lifting process, suddenly stop pulling the hand chain and check whether the brake can quickly and reliably stop, keeping the heavy object in a fixed position without slipping. Ensure that the braking distance is within the specified range. - Chain Tensile Test: Apply a certain tensile force to the chain and check whether the strength and elongation of the chain meet the standard requirements. Ensure that the chain will not break or cause other safety accidents during use. - No - load Running Test: Without applying a load, perform multiple lifting and lowering operations on the hand - operated chain hoist. Check whether its operation is smooth, and whether there are any abnormal noises such as friction and collision between components. Evaluate its operating flexibility and comfort. Safety Device Inspection - Overload Protection Device: Check whether the hand - operated chain hoist is equipped with an overload protection device, such as an overload limiter, etc., and conduct an overload test. When the load exceeds the rated value, the overload protection device should act in a timely manner to prevent the chain hoist from continuing to lift, thus preventing safety accidents caused by overloading. - Limit Device: Confirm whether a limit device, such as a lifting height limiter, is installed. Test whether it can accurately stop when the chain hoist reaches the set lifting height to avoid potential safety hazards caused by over - lifting. Material and Hardness Detection - Material Composition Analysis: Analyze the material composition of the main components of the chain hoist, such as hooks, chains, sprockets, etc., to ensure that the materials used meet the design requirements and relevant standards, and have sufficient strength, toughness, and wear resistance. - Hardness Detection: Use hardness testing equipment to detect the surface hardness of key components. The hardness value should be within the specified range to ensure the wear resistance and fatigue resistance of the components. Assembly Quality Inspection - Assembly Process Inspection: Check whether the assembly of components meets the process requirements, whether the connections between components are firm, and whether there are any phenomena such as looseness and misalignment. Ensure good assembly quality to guarantee the overall performance and stability of the hand - operated chain hoist.

- Lubrication Inspection: Check the lubrication of each moving part, whether an appropriate amount of lubricant has been applied, and whether the lubrication is uniform. Good lubrication can reduce friction between components, reduce wear, and extend the service life.

RELATED PRODUCTS .

Black Circular Sling for Truss Systems,A flexible loop-shaped lifting sling designed for stage trusses, lighting rigs, and performance equipment, primarily used for safely and efficiently hoisting and

**Virtual Rehearsal and Scene Simulation for Theatre Hoist Controllers** By integrating digital twin technology, the controller can simulate the coordinated movement of lighting, scenery, and actors

The core of hand chain hoists for small venue stages lies in **safety and portability**. During installation, it is essential to strictly follow the principle of vertical force application. During use

Electric hoists for concert stages can precisely match the needs of performances, balancing artistic presentation and technical safety to provide a reliable behind-the-scenes support system for concer

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record