X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

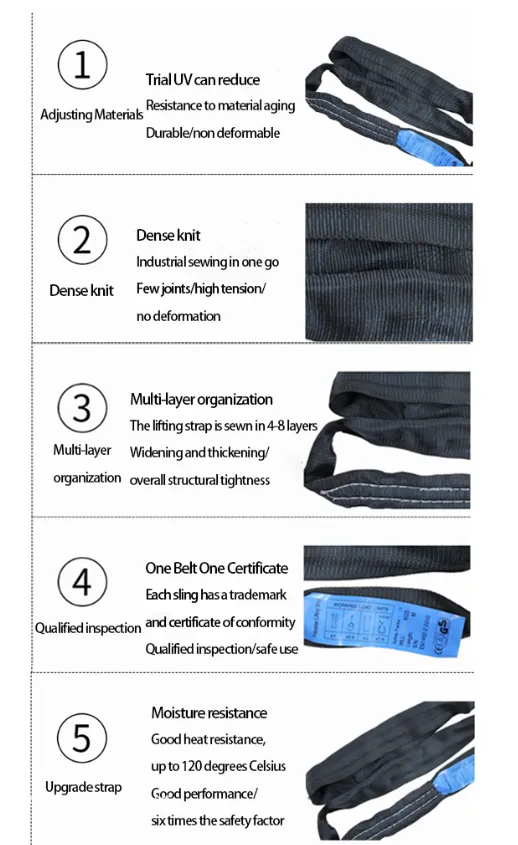

stage lifting slings are brightly colored, making it easy for workers to quickly identify and operate them on the stage. They also feature excellent abrasion resistance and chemical corrosion resistan

Category : Sling Series

Get a Quote

Product Details

To ensure the safety of the combination of stage electric hoists and lifting slings in different environments, measures can be taken from aspects such as equipment selection, installation and inspection, operation, and maintenance. The specific measures are as follows: Equipment Selection - **Match the Load - bearing Capacity**: Select electric hoists and lifting slings with appropriate load - bearing capacities according to the actual weight of stage equipment and usage requirements. The rated load of electric hoists and lifting slings should be far greater than the actual lifting weight. Generally, a safety factor of at least 1.5 times or higher is required to cope with possible emergencies. - **Consider Environmental Factors**: In special environments such as humid, high - temperature, and low - temperature conditions, choose electric hoists and lifting slings with corresponding protection levels and materials. For example, in a humid environment, the electric hoist should have good waterproof performance, and the lifting sling should be made of moisture - proof and corrosion - resistant materials. Installation and Inspection - **Install the Electric Hoist Correctly**: Install the electric hoist strictly in accordance with its installation instructions to ensure the correct installation position and firm fixation. The suspension point of the electric hoist should have sufficient strength and stability to bear the maximum load during lifting. - **Inspect the Lifting Sling**: Carefully check whether the lifting sling has damage such as wear, tearing, and broken wires before each use. If there are any problems, replace it immediately. At the same time, check whether the connection parts of the lifting sling are firm to ensure that there is no loosening or detachment during use. - **Conduct Overall Debugging**: After installation, conduct overall debugging and trial operation. Check whether the electric hoist runs smoothly and whether the lifting sling has phenomena such as deviation and distortion during the lifting process. If there are any abnormalities, adjust and repair them in a timely manner. Operation - **Operated by Professionals**: Arrange personnel who have received professional training and are familiar with the equipment performance and operation specifications to operate. The operators should understand the safety requirements for the use of electric hoists and lifting slings, and master the correct operation methods and emergency handling measures. - **Follow the Operating Procedures**: During the lifting process, strictly control the lifting speed, avoid rapid lifting or sudden braking to prevent excessive impact. Keep the lifting sling vertical during lifting, avoid tilting or slanting lifting to ensure that the load is evenly distributed on the lifting sling. - **Monitor the Environment**: When using in different environments, monitor the environmental conditions in real - time. For example, in a high - temperature environment, pay attention to the temperature changes of the electric hoist and the lifting sling to prevent performance degradation due to overheating. In a windy environment, take corresponding wind - proof measures, such as adding stabilizing ropes, to prevent the lifted object from shaking. Maintenance - **Maintain the Electric Hoist Regularly**: Regularly maintain the electric hoist, check the working conditions of components such as the motor, brake, and reducer, and replace worn - out parts in a timely manner. Clean the outer shell and internal components of the electric hoist to prevent the accumulation of dust and debris from affecting the equipment performance. - **Maintain the Lifting Sling**: After using the lifting sling, clean and organize it, and store it in a dry and ventilated place to avoid direct sunlight and chemical corrosion. Regularly inspect and test the lifting sling, such as conducting tensile tests, to ensure that its performance meets the requirements.

- **Record and Trace**: Establish a maintenance record file for the equipment, recording the time, content, problems found, and handling situations of each maintenance. This can be used to trace and analyze the equipment usage status, and discover potential safety hazards in a timely manner.

Previous: Easy Loading And Unloading Round Sling

RELATED PRODUCTS .

The polyester black lifting sling also features non-conductivity and no corrosion, ensuring safety and wide applicability. These characteristics make it an efficient and reliable hoisting tool, especi

The aircraft case truss hoist controller is suitable for the quick installation and adjustment of stage lighting, sound systems, and other equipment. It performs exceptionally well in enviro

Factory-direct hand-pulled stage hoists are ideal for the quick installation and adjustment of stage lighting, sound systems, and other equipment. They perform exceptionally well in environments witho

The stage truss motor equipped with a limit switch deeply integrates powerful performance, precise control, and excellent safety. It can not only easily handle the hoisting and accurate positioning of

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record