X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

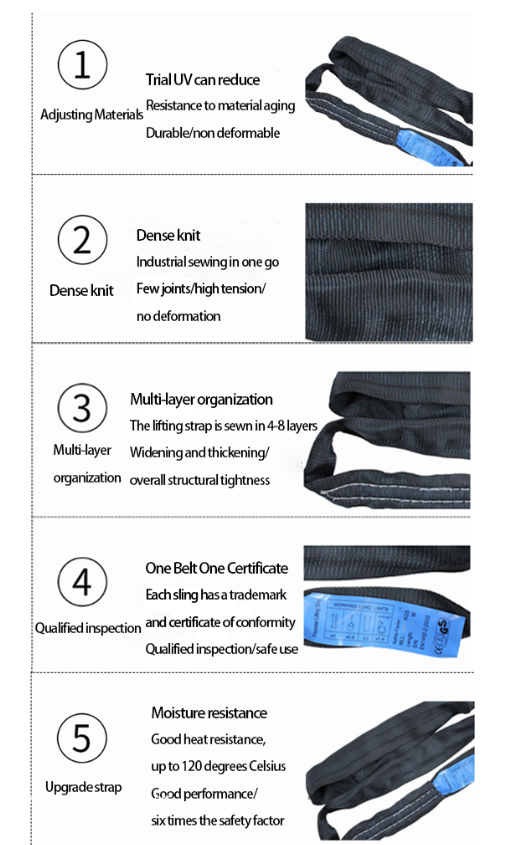

1. Precautions for using lifting belts and rigging equipment

Category : Sling Series

Get a Quote

Product Details

1. Precautions for using lifting belts and rigging equipment

(1) Do not drag in parallel and avoid shaking and forcefully grabbing the load caused by the lifting belt.

(2) Before using the lifting belt, carefully inspect it and do not use damaged lifting belts.

(3) When lifting, do not twist or twist the lifting belt, and do not let the lifting belt knot when using.

(4) Avoid tearing open sewing joints or overloading work.

(5) Without a protective cover, the lifting belt shall not lift steel plates, workpiece molds, or other goods with sharp edges or corners that may harm the lifting belt.

2. Maintenance methods for lifting belts and slings

(1) For damp lifting belts, they should be dried and stored to avoid moisture and mold.

(2) Lifting straps should be placed away from heat sources (flames and electrical welding) or under conditions of long-term exposure to sunlight and ultraviolet radiation.

(3) The lifting belt should be stored on a shelf after use and should not be placed directly on the ground to prevent mold and rodent bites after use.

(4) The lifting belt should be cleaned once every 3-6 months of use. For acidic or alkaline use, clean the lifting belt with cold water or cleaning agent after use, dry and store it.

3. Scrapping standards for lifting belts and slings

(1) When lifting with horizontal edge cutting, it should be scrapped.

(2) When the lifting belt is severely twisted, deformed, or fuzzed, it should be scrapped.

(3) When lifting with local scratches or scratches from sharp objects, it should be scrapped.

(4) When the lifting belt body is cut, severely scratched, the belt strands are loose, or locally ruptured, it should be scrapped.

(5) When the surface of the lifting belt is severely worn or deformed, and the wear reaches 1/10 of the original width of the lifting belt, it should be scrapped.

(6) When the lifting belt becomes moldy, deteriorated, burned by acid or alkali, melted or charred by heat, or has multiple loose or corroded surfaces, it should be scrapped.

(7) When synthetic fibers experience softening or aging (yellowing), rough surface, peeling, elastic changes, or weakened strength, they should be scrapped.

Previous: Soft Sling Webbing Nylon Sling Belt

RELATED PRODUCTS .

Product Name: Stage Chain Hoist Product Type: Stage Chain Hoist Product Description: Tianjin Kemei Machinery Manufacturing Co., Ltd. is a modern production - oriented enterprise integrating independ

The lifting slings used for truss erection are made of high-strength synthetic fiber materials. They not only possess excellent strength, capable of withstanding a large pulling force, but also have r

The use of different voltages in the circuit of a stage truss chain hoist controller is mainly based on safety, equipment compatibility, and specific application requirements. A 36V safety voltage can

The double brake system of the stage lighting hoist not only significantly improves the safety performance but also brings many excellent performance advantages to the electric chain hoist for the sta

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record