X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

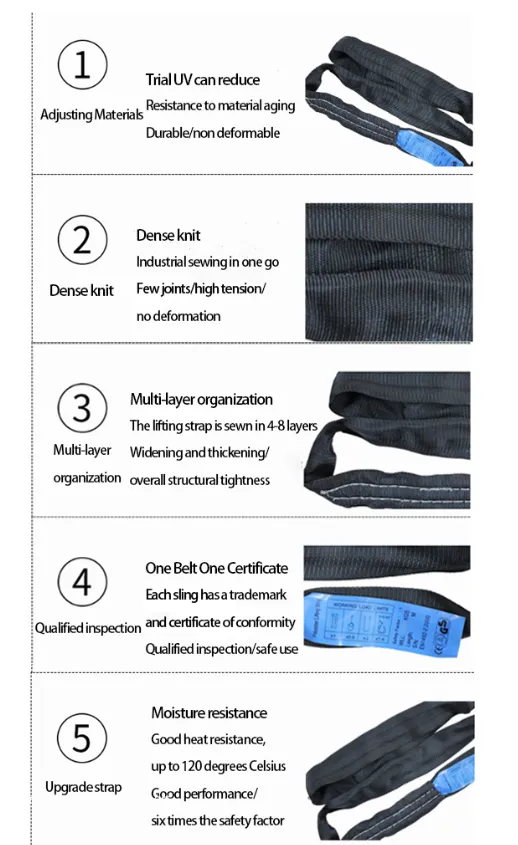

Stage lifting slings are crucial tools for lifting and transporting stage equipment. Usually made of high - strength synthetic fibers, they are lightweight and highly flexible, facilitating arrangemen

Category : Sling Series

Get a Quote

Product Details

Lifting slings are flexible lifting riggings used for hoisting and transporting goods. The following is a detailed introduction to their usage methods and applications: Usage Methods 1. Select the Appropriate Lifting Sling: Based on factors such as the weight, shape, size of the object to be lifted, and the lifting environment, choose a lifting sling of the appropriate specifications and types. This includes considering parameters such as the rated load, length, and width of the lifting sling to ensure that it can safely bear the object to be lifted. 2. Inspect the Lifting Sling: Before use, carefully check whether the lifting sling has defects such as damage, wear, breakage, deformation, or aging. If any problems are found, stop using it immediately and replace it with a new one. At the same time, check whether the labels and markings on the lifting sling are clear and complete to confirm its specifications and performance. 3. Proper Hoisting - Hoisting with a Single Lifting Sling: Put the loop end of the lifting sling over the lifting tool (such as a hook), ensure that the lifting sling is firmly connected to the lifting tool. Then, wrap the flat part of the lifting sling around the object to be lifted, place the object at the center of the lifting sling, and tighten the lifting sling to make it fit closely with the object. - Hoisting with Multiple Lifting Slings: If multiple lifting slings are used for hoisting, ensure that the lengths of all lifting slings are equal, they are evenly distributed around the object to be lifted, and the angles between them are appropriate to ensure that each lifting sling bears the load evenly. Generally, the angle between two lifting slings should not exceed 60 degrees. For three or more lifting slings, the angles should be reasonably allocated according to the actual situation. 4. Lifting Operation: During the lifting process, maintain a stable and slow speed, avoid sudden acceleration, deceleration, or shaking to prevent the object from swinging or colliding. At the same time, constantly observe the condition of the lifting sling. If there is any abnormality, stop lifting immediately. 5. Placement and Fixation: After the object is lifted to the designated position, lower it slowly and smoothly to ensure that the object is placed stably. In cases where the object needs to be fixed, use appropriate fixing devices to securely fasten the lifting sling to the object to prevent it from moving or slipping. 6. Post - use Handling: After use, promptly clean the dirt and debris on the surface of the lifting sling, neatly roll or fold it, and store it in a dry, ventilated place without direct sunlight. Avoid contact with sharp objects to prevent scratching the lifting sling. Applications - Industrial Field: In places such as factories, mines, and construction sites, it is used to lift various mechanical equipment, components, raw materials, etc. For example, in an automobile manufacturing factory, lifting slings can be used to lift components such as automobile engines and vehicle bodies; at construction sites, they can be used to lift construction steel, precast slabs, steel beams, etc. - Logistics and Warehousing: In logistics warehouses, port terminals, etc., it is commonly used for loading, unloading, and transporting goods such as containers, palletized goods, and large - scale equipment. It can facilitate the lifting and transportation of goods, improving the efficiency of logistics operations. - Shipbuilding and Ship Repair: During the shipbuilding and ship repair processes, lifting slings can be used to lift large equipment and components such as ship main engines, boilers, masts, as well as the lifting and assembly of ship hull segments. - Aerospace: In the aerospace field, it is used for lifting and transporting components such as aircraft engines and wings, as well as the assembly operations of spacecraft components. Due to the high precision and high value of aerospace equipment, the requirements for the safety and reliability of lifting slings are extremely high. - Culture and Sports: In activities such as stage performances and sports events, lifting slings can be used to hang lighting equipment, audio equipment, stage scenery, etc., ensuring the safe installation and stable operation of these devices, and providing support for performances and events.

- Daily Life: In some daily life scenarios, such as moving furniture, large - scale electrical appliances, etc., lifting slings can also be used to facilitate the handling.

Previous: Polyester Flat Webbing Lifting Sling

RELATED PRODUCTS .

The polyester black lifting sling also features non-conductivity and no corrosion, ensuring safety and wide applicability. These characteristics make it an efficient and reliable hoisting tool, especi

The aircraft case truss hoist controller is suitable for the quick installation and adjustment of stage lighting, sound systems, and other equipment. It performs exceptionally well in enviro

Factory-direct hand-pulled stage hoists are ideal for the quick installation and adjustment of stage lighting, sound systems, and other equipment. They perform exceptionally well in environments witho

The stage truss motor equipped with a limit switch deeply integrates powerful performance, precise control, and excellent safety. It can not only easily handle the hoisting and accurate positioning of

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record