X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

The maintenance cycle of the lifting belt should be determined by relevant inspection technicians based on the usage situation, usage environment, usage frequency, and such practical application facto

Category : Sling Series

Get a Quote

Product Details

Daily inspection and maintenance of lifting belts

The maintenance cycle of the lifting belt should be determined by relevant inspection technicians based on the usage situation, usage environment, usage frequency, and such practical application factors. If it is frequently used and the lifted object is heavy, it can be considered to check before and after each lifting. If the lifting is not frequent but occurs every day, it can be checked according to the number of times. No matter how the inspection is carried out, the more times the inspection is carried out within the allowable range of conditions, the better.

If used occasionally, in addition to ensuring the storage environment, it should be ensured that at least annually, the synthetic fiber lifting belt should be visually inspected by inspectors to determine whether it can continue to be used. A record of such testing should be kept.

Damaged lifting straps should not be used again. Please do not repair it yourself.

Is the reason for the long service life of lifting belts due to their uniform force distribution?

As is well known, whether it is flexible lifting straps, white lifting straps, or colored lifting straps, they are all woven from polyester or polypropylene fibers. The key point is that polyester and polypropylene fibers are woven continuously during the process of weaving lifting belts. If there are a large number of broken threads in the weaving process, it is considered an unqualified lifting belt product.

As a result, the entire lifting belt has a complete wire structure, and during the use of the lifting belt, each wire woven into the lifting belt carries weight, and each polyester/polypropylene wire woven into the lifting belt carries weight very evenly.

It is precisely because of this obvious advantage that the breaking load of industrial lifting belts is several times greater than the standard bearing weight.

This is also why large tonnage lifting belts should not come into contact with sharp edges or objects during lifting. Once the lifting belt comes into contact with sharp objects during the lifting process, the body of the lifting belt will be cut. As a result, the entire weight bearing capacity of the lifting belt will be uneven, and its original standard bearing capacity will disappear, reducing the breaking load several times. Losing the original structural form and mechanical bearing performance of the entire lifting belt

RELATED PRODUCTS .

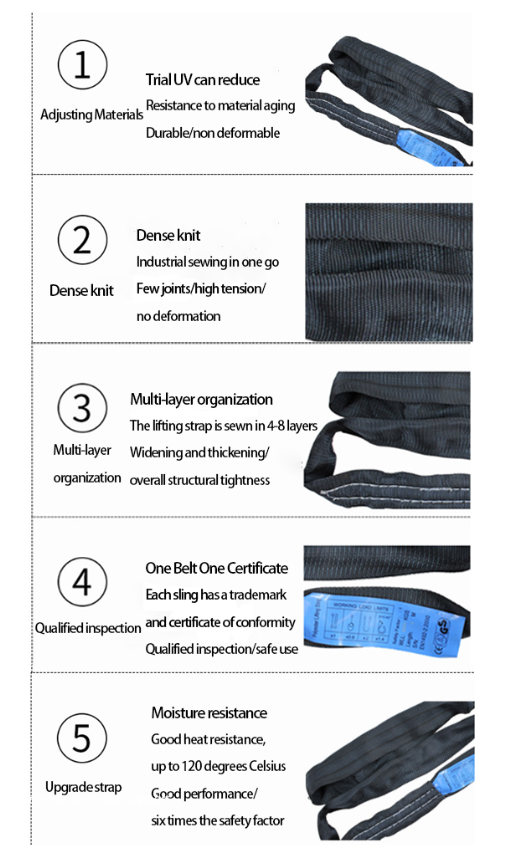

The polyester black lifting sling also features non-conductivity and no corrosion, ensuring safety and wide applicability. These characteristics make it an efficient and reliable hoisting tool, especi

The aircraft case truss hoist controller is suitable for the quick installation and adjustment of stage lighting, sound systems, and other equipment. It performs exceptionally well in enviro

Factory-direct hand-pulled stage hoists are ideal for the quick installation and adjustment of stage lighting, sound systems, and other equipment. They perform exceptionally well in environments witho

The stage truss motor equipped with a limit switch deeply integrates powerful performance, precise control, and excellent safety. It can not only easily handle the hoisting and accurate positioning of

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record