X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

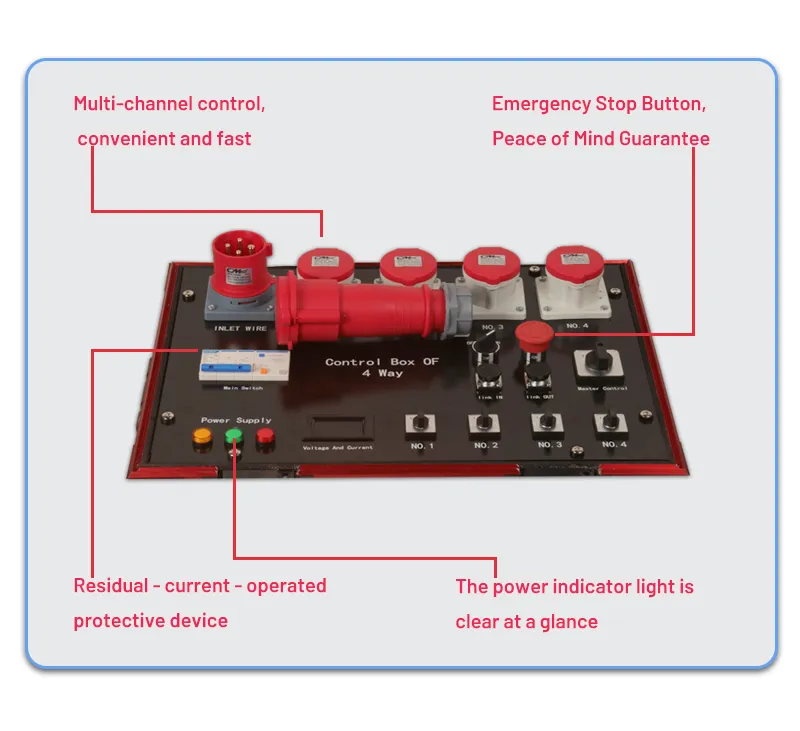

Electric Hoist Control Box. With one - key precise scheduling, it enables the curtains to open and close, and props to rise and fall as you wish, injecting a smooth magic into stage performances! Ther

Category : Controller

Get a Quote

Product Details

The installation steps of the stage electric hoist control box are generally as follows: Preparation before Installation 1. Equipment Inspection: Carefully check whether the control box and related accessories are complete, and whether there is any damage, deformation, etc. Ensure that the appearance of the control box has no defects, and there are no problems such as loose or fallen - off internal circuit components. At the same time, check whether the various performances of the electric hoist are normal and whether its compatibility with the control box is good. 2. Tool Preparation: Prepare the tools required for installation, such as screwdrivers, wrenches, electric drills, wire strippers, multimeters, etc., and ensure that the tools are complete and can be used normally. 3. Location Determination: Determine the installation location of the control box according to the stage layout and the installation location of the electric hoist. Generally, it should be selected in a place that is easy to operate and observe, and is not easily affected by collisions and interference. At the same time, consider the convenience of wiring and try to shorten the distance between the control box and the electric hoist to reduce line loss. Installation of the Control Box 1. Fixing the Control Box: Use tools such as screwdrivers or electric drills to fix the control box in the pre - determined position. It can be fixed by means of expansion bolts or screws to ensure that the control box is firmly installed and will not loosen due to vibration or other factors. 2. Connecting the Power Cord: Connect the appropriate power cord according to the rated voltage and power requirements of the control box. First, cut off the power supply, then use a wire stripper to peel off the outer skin of the power cord. According to the markings on the control box, connect the live wire, neutral wire, and ground wire of the power cord to the corresponding terminal blocks respectively. After the connection, use a multimeter to check whether the line connection is correct and whether there are problems such as short - circuits or open - circuits. 3. Connecting the Control Lines: Connect the control lines between the control box and the electric hoist. Usually, there are wires of different colors on the control lines, corresponding to different control functions of the electric hoist, such as up, down, stop, etc. According to the markings on the control box and the electric hoist, accurately connect each wire of the control line to the corresponding terminal block. During the connection process, pay attention to the firmness of the wire connection to avoid loose connections. 4. Grounding Treatment: To ensure safety, the control box must be well - grounded. Connect the grounding terminal of the control box to a reliable grounding body through a dedicated grounding wire. The grounding resistance should meet the requirements of relevant standards, generally not more than 4 ohms. The grounding connection should be firm and reliable, and no looseness is allowed. Debugging and Testing 1. Line Inspection: Before power - on, carefully check again whether the connections of all lines are correct and firm, and whether there are any missed or wrong connections. Only after ensuring that the line connections are correct can the next step be carried out. 2. Power - on Testing: Turn on the power supply and observe whether the power indicator light of the control box is normally on. Use tools such as a multimeter to measure whether the output voltage of the control box is normal, and check whether each control function can be normally realized. For example, when pressing the up button, whether the electric hoist can rise normally, and when pressing the stop button, whether the electric hoist can stop immediately. 3. Function Debugging: Debug the functions of the electric hoist such as speed adjustment and limit setting. According to actual needs, adjust the speed - adjustment knob on the control box to check whether the running speed of the electric hoist meets the requirements. At the same time, set the upper and lower limit switches of the electric hoist to ensure that the electric hoist will not exceed the set travel range during operation. 4. Safety Testing: Test the safety protection functions of the control box, such as overload protection and leakage protection. The control box can be checked to see if it can cut off the power supply in a timely manner to protect the safety of equipment and personnel by simulating overload or leakage situations. Inspection and Arrangement after Installation 1. Overall Inspection: After the installation is completed, conduct a comprehensive inspection of the entire system, including whether the control box is firmly installed, whether the line connections are neat and beautiful, and whether the operation of the electric hoist is stable. Ensure that the entire system is installed correctly and operating normally. 2. Site Cleaning: Clean up the sundries and garbage generated during the installation process to keep the installation site clean. Organize the tools and put them back in place for proper storage.

3. Record Archiving: Record the installation process and debugging results, including information such as the model of the control box, installation location, line connection situation, and debugging data. Organize these records into a book and archive them for future maintenance and repair.

RELATED PRODUCTS .

Customizable Sling Belts With "design-on-demand" at their core, customizable sling belts deeply integrate materials science, mechanical principles, and scenario-specific needs, making them i...

As the "brain" of lifting tools, the performance of truss hoist controllers directly impacts stage effects and operational safety. From manual operation to intelligent linkage, different typ...

The smooth manual chain hoist, with its reliable mechanical structure and operational flexibility, has become an indispensable manual lifting tool in scenarios such as stages, industrial environments,

Efficiently complete rapid setup of booth trusses, high-altitude suspension of product display racks, or multi-angle display of dynamic advertising light boxes. For example, at a technology exhibition

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...

2025-02-27

创始人

0

Guangzhou (International) Performing Arts Equipmen...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-02-27

创始人

0

GET show Guangzhou (International) Performing Arts...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2024-09-24

admin

0

Tianjin Kemei Machinery Manufacturing Co., Ltd. Ne...

Tianjin Kemei Machinery Manufacturing Co., Ltd.: New Starting Point, New Journey - New Factory Relocation Record